Building the critical facilities for the UK’s life sciences and technology ambitions

The United Kingdom (U.K.) wants to become a sciences powerhouse. Safe, highly controlled good manufacturing practice (GMP) facilities — housing the research, development and manufacture of new innovations and products — are essential to achieving this goal. While such facilities are in short supply, industry and investors are now turning their attention to these spaces, as Alison Wring, Tracy D’Souza and Paul Melton report.

GMP is a protocol by which regulated products — typically items like medicines, food products and cosmetics — are manufactured under standardised conditions.

The goal is to create safe products which meet stringent industry and government regulations and avoid unsafe or contaminated products. Given the tightly controlled nature of such manufacturing, the physical buildings where GMP products are made call for high levels of safety, hygiene and process visibility.

GMP facilities not only manufacture established products, but also test emerging technology, foods, medicines and processes before final approval and mass market release. They serve as the bridge or ‘pilot plant’ between small-scale research and development laboratory facilities testing novel or trial products, and eventual large-scale factory production.

Right now, there are economic, political and social drivers making GMP facilities an industry and government focus in the U.K..

In July 2025, the U.K. government published a new Life Sciences Sector Plan, aiming for the U.K. to lead Europe in life sciences by 2030, and to rank third globally behind China and the United States (U.S.) by 2035. It committed £520 million towards manufacturing, targeting advanced therapies. It also wants to reduce the time it takes for products to reach the market, streamlining approvals processes.

GMP facilities thus have huge potential to drive productivity and innovation in the U.K., with researchers and manufacturers alike seeking affordable, low-carbon, high-quality GMP sites.

“In July the U.K. Government published its new Life Sciences Sector Plan, setting ambitious goals to lead Europe in life sciences by 2030 and rank third globally behind China and the U.S. by 2035.”

Scaling up GMP facilities across the U.K.

Regulated products such as medicines typically follow a development trajectory, starting with research at universities, labs and research centres, through to proof of concept, prototyping, to pilot scale ups — at GMP facilities — through to eventual full manufacturing and distribution.

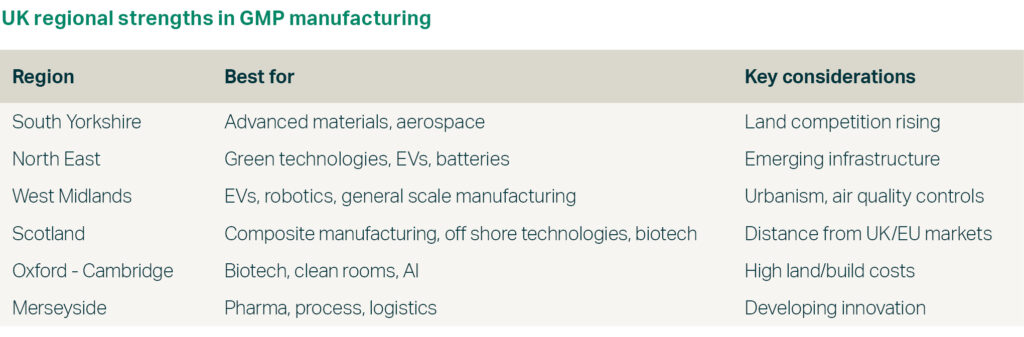

The U.K.’s compact nature means that GMP facilities can be situated at an accessible distance to most initial research sites. GMP facilities therefore do not need to be in central London, or the Oxford-Cambridge-London ‘golden triangle’ of life science innovation and study.

Instead, across the U.K., regional GMP centres of excellence are emerging, specialising in specific products and processes.

Developing GMP sites across the U.K. has the significant benefit of providing quality regional employment. People with logistics or factory experience can be quickly upskilled to work within these facilities, boosting local work and education opportunities.

Design considerations

As with all factories, GMP facilities should be able to meet the needs of a range of different individual, yet interconnected processes. Standard features include a manufacturing space, a storage warehouse for raw and finished product, loading bays, and supporting lab and office areas.

GMP shell building design tends to be simple. Externally, standalone facilities often feature a portal roof frame and a rainscreen cladding system. Internally, production and manufacturing typically take place on the ground or basement level. A mezzanine floor level enables the full production flow to be monitored, and any problems or bottlenecks identified. For multifunctional sites, office, laboratory, and corporate functions are usually located on above-ground floor levels.

Prioritising sustainability and social value from the start

Running 24/7, required to meet stringent International Organization for Standardization (ISO) standards, and to achieve highly specific temperature, air pressure and humidity levels, GMP buildings are power intensive. Therefore, they tend to have a high operational carbon output. In the future, these production facilities will likely come under scrutiny for their power, water and cooling demands.

To mitigate this, planning and designing should be undertaken with an understanding of other building demands. GMP facilities are a driver of economic growth, but they also need to be planned carefully to avoid detracting from other national development objectives, like housing, education, health and technology.

New GMP facilities should be prioritised in regions where there is currently less strain on water and power supply, and where there is a clear benefit to supporting local employment and upskilling.

Other sustainability measures include:

- Passive design measures such as highly energy efficient HVAC plant, heat recovery systems and high efficiency LED lighting

- Smart controls should be incorporated to actively minimise energy consumption

- Renewable and low-carbon energy and heat sources

- Water consumption can be reduced via low flow fixtures and fittings, and water recycling systems.

- Effective waste management and recycling systems, alongside continuous operational energy monitoring.

Procuring locally available components and materials also reduces carbon footprint, improves social value and reduces the risk of supply chain and transportation delays. Where appropriate, the opportunities for modern methods of construction (MMC) with package plant and pre-fabricated systems can also support reduced waste and provide health and safety benefits.

Unlocking the U.K.’s life sciences and technology ambitions

GMP facilities are a vital cog in the wheel for industries such as pharmaceuticals, biotechnology, food and energy to flourish. They are essential to safeguard public health, ensure product quality and maintain the U.K.’s regulatory alignment and competitiveness in global industries.

However, there is a shortage of flexible, low-carbon, dedicated buildings to support the U.K.’s scientific superpower goals. Post-Brexit, regulatory changes and rising demand have stretched U.K. analytical and batch-testing infrastructure to its limits. A 2025 report from think tank The Centre for Long-Term Resilience described the U.K. as “perilously vulnerable” in its pharmaceutical manufacturing capacity.

For the U.K. to fulfill its life sciences and technology ambitions, the gap must be bridged between research and development and mass manufacture. New GMP facilities are the key to unlocking this.

This is an abridged version of an article that was first published in Building magazine. You can read the full article here.

Cost model: GMP facilities

This cost model is based on a speculative project in the northwest of England with a gross internal area (GIA) of 3,600 square metres and comprises roughly a 50/50 split on GMP laboratories and office and write up space. It is based upon a two-stage procurement strategy and utilises a Joint Contracts Tribunal (JCT) contract.

It has been designed to achieve sustainable building certification BREEAM’s highest Outstanding rating.

Click here to download the cost model.