Hydrogen and the water challenge

The emergence of a green hydrogen energy industry in Australia is an exciting prospect and demonstrates our national commitment to a significant global challenge. The energy and water sectors must work together to expedite this transition.

The urgent need to lower global carbon emissions is driving innovation, investment and policy support to decarbonise the energy and transport sectors, with green hydrogen touted as a vital part of the puzzle. According to Bloomberg New Energy Finance, 26 countries now have national hydrogen strategies, up from 15 in 2021. These strategies typically set deployment targets and public investment commitments, providing conditions for further investment in the hydrogen sector.

A versatile energy carrier with many potential applications, hydrogen has the potential to play a significant role in the energy transition. Hydrogen is a zero-emission energy carrier that can be used to store, transport and export renewable energy when produced using renewable energy via electrolysis. Potential applications for hydrogen include heavy transportation, heating and chemical input for industrial processes and integration into the electricity grid through ancillary services. Hydrogen can also be used to export renewable energy in the form of liquid hydrogen, ammonia or other hydrogen-dense media.

While the jury may still be out on the ultimate significance of hydrogen’s role in our future energy mix, there is no doubt that hydrogen will play a part in our transition to a lower carbon economy. The International Energy Agency estimated that annual global hydrogen demand could increase from ~11 EJ in 2021 to ~63 EJ by 2050 (in the net zero by 2050 scenario).

Water for hydrogen

Large-scale green hydrogen production via electrolysis is highly water intensive. The electrolysis process, which uses electricity and catalysts to split water molecules into hydrogen and oxygen, requires approximately 9 kg of water for each kilogram of hydrogen produced (on a purely stoichiometric basis). Depending on the type of electrolyser used and the intended end use of the hydrogen, this water usually needs to be of very high purity – demineralised and deionised.

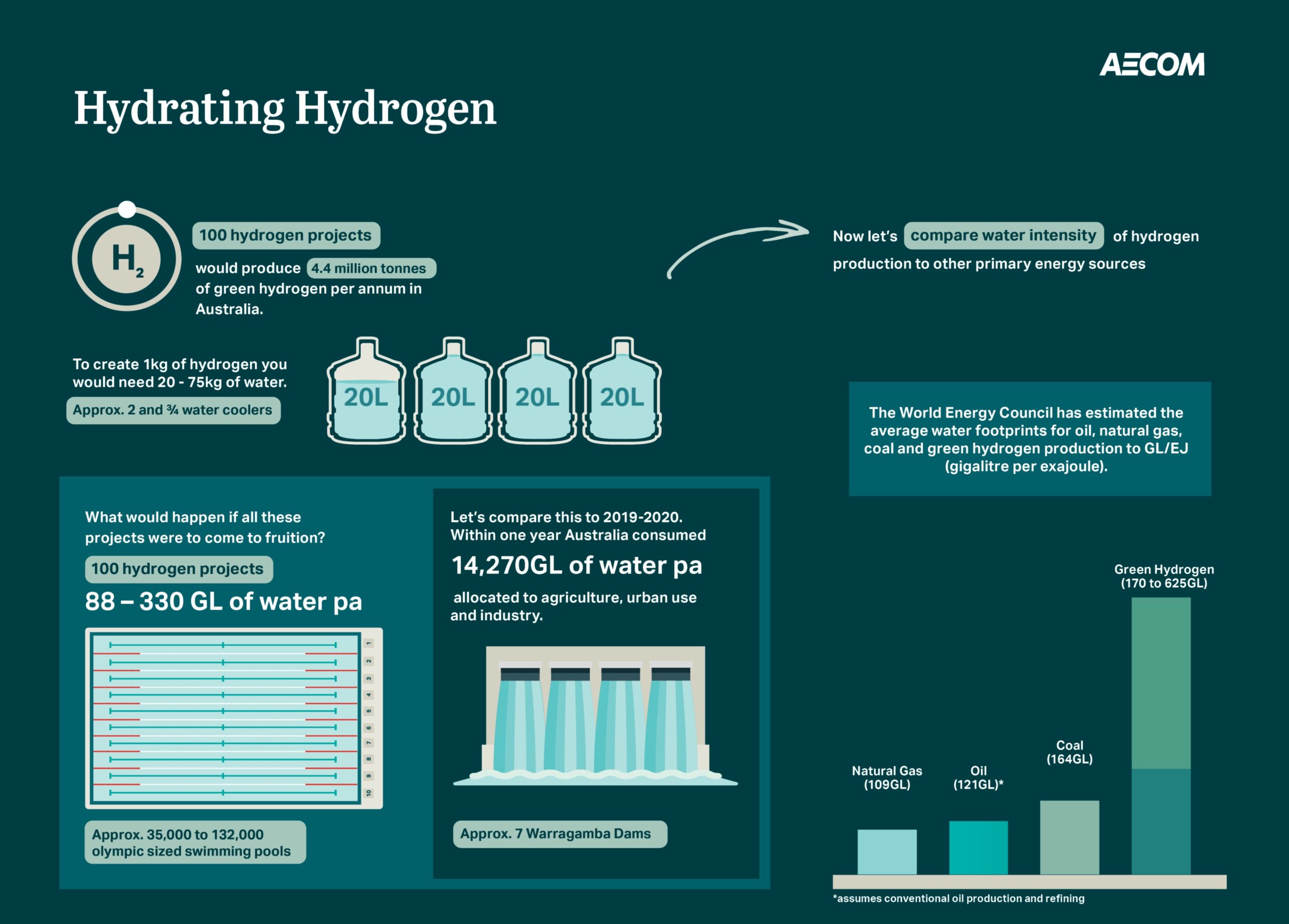

Additional water is required in the production process to support the balance of plant and electrolyser operations, primarily for cooling purposes. Depending on the quality of the water feedstock, the required hydrogen specifications, and the balance of plant requirements, this water usage can be material, adding anywhere between 10 kg to 65 kg of water per kg of hydrogen produced, bringing the total water requirement to ~20 kg to 75 kg (per kilogram of hydrogen produced). While these requirements are material, there is some good news. The balance of plant water can be lower quality than that used in the electrolysis process, some of it may be recovered and recycled in the process, and, in some applications, air cooling can be substituted for water cooling.

Water availability and ramping up hydrogen production

The Australian hydrogen industry is still in its infancy; however, there are many proposals to develop hydrogen ‘hubs’ that will co-locate production facilities alongside large industrial users and export facilities. There are also several existing small-scale pilot plants located in industrial estates close to urban centres.

There are currently almost 100 proposed projects aiming to produce approximately 4.4 million tonnes of green hydrogen per annum in Australia for both domestic consumption and export. Given that each kilogram of hydrogen production requires ~ 20-75 kg of water, the total water requirement would be ~88 – 330 GL per annum if all these projects were to materialise. For comparison, in 2019-20, a total of 14,270 GL of water was consumed in Australia, with 67% allocated to agriculture, 22% to urban use and 11% (1570 GL) to industry.

The World Energy Council (WEC) estimates that the average water footprints for primary energy production of oil, natural gas, and coal are, respectively, 121 (based on conventional oil production and refining), 109 and 164 GL/EJ. It’s worth noting that estimates for oil vary significantly due to the assumed production method, with unconventional methods being significantly more water-intensive. With current green hydrogen production methods, we estimate the water footprint to vary in the range of 170 – 625 GL/EJ (based on the lower heating value for hydrogen), depending on several factors, including the input water quality, cooling requirements and methods, and the hydrogen production technology employed.

The Australian water challenge

Australia is facing significant water availability challenges, including managing environmental flows, meeting agricultural demands, servicing industry needs and accommodating urban growth. This delicate balancing act aims to meet societal demands for water whilst ensuring enough for the environment. This has led to the development of some of the world’s most innovative and progressive water management plans and strategies. While Australia is considered a global leader in the management of water resources, both at a regional and a metropolitan scale, hydrogen production is yet to feature in these plans as a significant demand. This disconnect between the energy and water sectors becomes more apparent when reviewing their respective long-term plans.

Limitations to the growth of the hydrogen industry

Theoretically, sourcing water for green hydrogen production shouldn’t limit national ambitions to decarbonise the economy because we can implement strategies to meet this demand, including desalination and treated wastewater. However, additional investment and energy consumption are required to support extra water processing requirements. At the local scale, hydrogen production for a future energy demand scenario could directly compete with other water users. Limitations on water availability caused by supply or water infrastructure constraints in some locations may also limit the growth potential of the hydrogen industry. This is particularly relevant to the existing and proposed hydrogen facilities in urban or industrial settings.

Moving forward

The emergence of a green hydrogen energy industry in Australia is an exciting prospect and a tangible demonstration of our national commitment to a significant global challenge. The energy and water sectors must work together to expedite this transition.

For the water sector, this means understanding the national hydrogen ambition and determining what that means locally, considering the current and future water cycle, environmental needs, water use and water supply assets. Once all the constraints and opportunities have been determined, organisational commitments should also be embedded in the relevant plans and strategies that aspire to protect the water cycle.