NEC: Lessons from Hong Kong’s infrastructure evolution

In the complex world of infrastructure delivery, how can we better manage risk, foster collaboration and drive innovation?

One answer lies in the adoption of the NEC suite of contracts.

Drawing on over a decade of New Engineering Contract (NEC) experience, Francis Leong, Project Management Lead in AECOM’s Hong Kong business, shares how NEC has reshaped project delivery for clients and the lessons learnt.

From adversarial to collaborative: A cultural shift in contracting through NEC

Hong Kong’s transition from the traditional General Conditions of Contract (GCC) to NEC began over a decade ago, driven by the need to address cost overruns and delays in public infrastructure. The GCC, based on common law principles, often led to reactive dispute resolution and prolonged claims processes. In contrast, NEC promotes proactive, real-time collaboration between clients, contractors and consultants.

“NEC provides a better platform for people to collaborate and solve problems early,” says Leong. “It’s not just about the contract, it’s about mindset.”

This shift has been particularly impactful for projects with complex stakeholder environments, such as rail and aviation. The emphasis of NEC on early warning mechanisms, shared risk and target cost models has enabled faster decision making and reduced adversarial behaviours.

NEC in action: The bridge rotation breakthrough

One of the most compelling examples of NEC’s potential is the Kwu Tung North and Fanling North New Development Area (NDA) Phase 1 project. When high-voltage power cables running across a live railway corridor unexpectedly obstructed the project, the team had to rethink its approach.

Rather than default to costly delays, the team proposed a bridge rotation technique over live railway tracks that had never been used in Hong Kong. This set a new benchmark for efficiency and safety by saving twelve months of construction time.

The bridge was constructed adjacent to the railway and rotated into place in a single night, dramatically reducing disruption to train services and safety risks.

“This was made possible because of the trust built through NEC,” Leong explains. “The client CEDD, contractor CRCC-Paul Y JV, and AECOM worked together to find a solution that balanced cost, time and safety.”

There was also the world’s first use of ultra-high-strength S960 steel in footbridge construction under this project. Not only did it achieve a remarkable reduction in the superstructure’s weight, but it also enhanced construction safety.

Every NEC Contract includes a core clause requiring all parties to act in a spirit of mutual trust and cooperation. This is legally binding and sets the collaborative tone from the outset.

The project was recognised as a runner up in the worldwide 2025 Martin Barnes NEC Innovation Awards for project excellence and innovation, demonstrating how contractual frameworks can enable, not inhibit, emerging ingenuity.

Another example of project delivery excellence through collaborative partnering is the Yuen Long Effluent Polishing Plant project, which won the NEC Martin Barnes 2024 Award for project excellence and innovation. It was recognised for its innovative use of technologies and advanced sewage treatment systems to enhance energy efficiency, as well as its collaborative management techniques that led to smooth delivery.

Measuring what matters in NEC projects

While NEC contracts are designed to foster collaboration and innovation, their success ultimately hinges on how performance is managed.

The Early Warning Mechanism in each contract encourages proactive problem-solving and joint decision-making. Parties must notify each other of any risks or issues that can affect cost, time or quality.

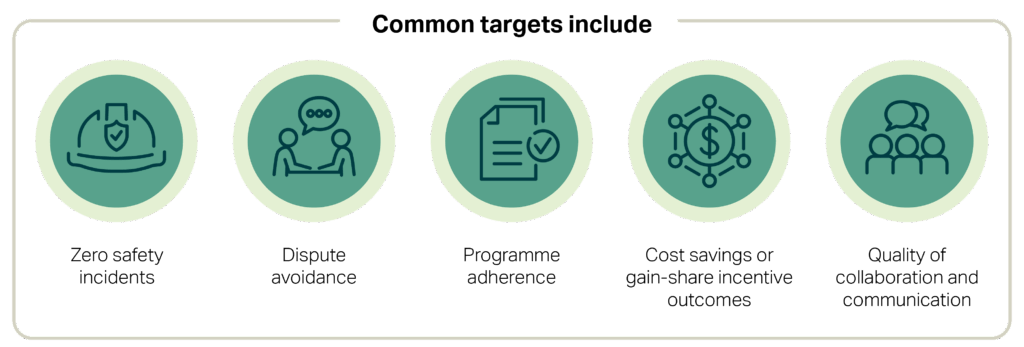

Although NEC doesn’t prescribe specific key performance indicators, it creates conditions for meaningful metrics to emerge. Common targets include:

NEC’s emphasis on early warning systems and programme management helps clients and delivery teams identify risks early, enabling smarter decisions and better outcomes.

Building capability: AECOM’s NEC Handbook and training program

Transitioning to NEC required a significant uplift in capability. AECOM responded by developing the AECOM NEC Administration Handbook to provide practical guidance across the AECOM business on key processes such as:

- Early warning notifications

- Programme assessment

- Compensation event management

- Payment certification under target cost contracts

This was supported by a comprehensive training programme for over 2,200 resident site staff and office-based engineers, ensuring consistent application of NEC principles across all projects. A key enabler of making NEC work for clients is the investment into training and uplift of staff.

“We’re not just delivering projects; we’re building an internal culture of proactive contract management which we then use to deliver value for our clients and partners.”

Lessons learnt: Why NEC matters now

As our clients navigate increasingly complex delivery environments, the lessons learnt are timely:

While NEC may not be the right fit for every project, it offers a compelling alternative for clients seeking greater control, transparency, and quick, joint decision-making in high-risk, multi-stakeholder environments.