Platform-based construction ecosystems

This year’s HOUSING • I&T Summit, a flagship initiative under the Hong Kong SAR Government’s “HOUSING • I&T Year 2025” brought together local and international experts to explore how innovation can transform the future of public and affordable housing. At the heart of the discussions was how smart innovation — ranging from AI and digital twins to modern methods of construction and advanced materials — is reshaping the built environment.

In his keynote, “Platform-based Construction Ecosystems”, Marc Colella, Strategy and Growth Lead Asia and ANZ, and AECOM Fellow, examined how emerging technologies and global best practices can help global cities like Hong Kong build faster, cleaner and more sustainably.

Like many global cities, Hong Kong faces a challenging paradox: demand for high-quality, affordable housing is increasing, yet traditional construction methods are struggling to meet timelines, cost expectations and sustainability requirements. Across the industry, skilled labor shortages, supply chain disruptions and rising carbon targets are adding further pressure.

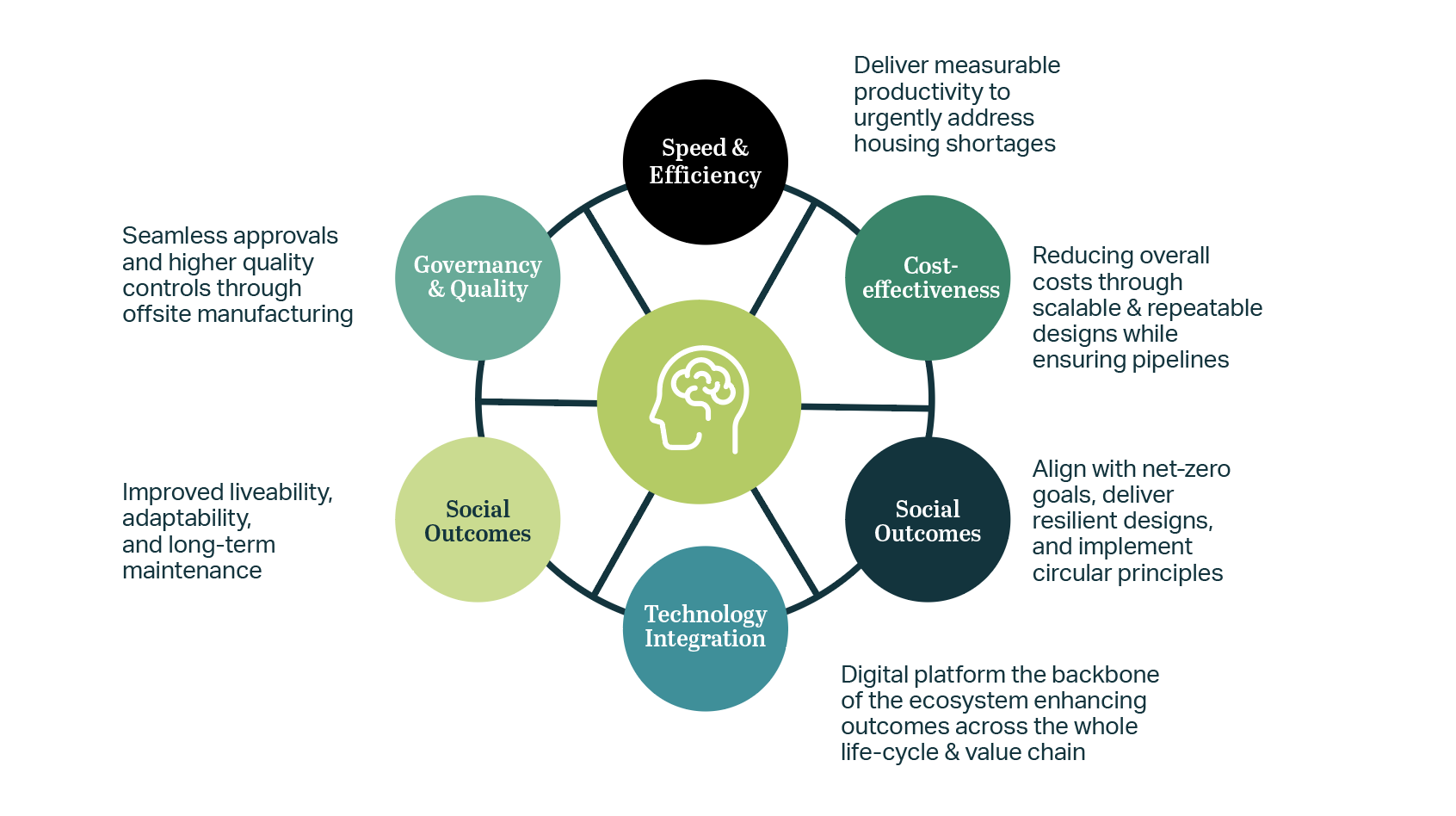

Key drivers guiding housing innovation and system reform

The shift toward an industrialized, platform-based housing model is guided by a set of core objectives that align productivity, cost, sustainability and quality with long-term public needs. These include:

- Speed and efficiency – Improving delivery productivity to meet urgent housing demand.

- Cost-effectiveness – Reducing overall costs through scalable, repeatable and pipeline-aligned solutions.

- Sustainability – Supporting net-zero goals through low-carbon, circular and resilient design approaches.

- Technology integration – Using a unified digital platform to enhance outcomes across the full value chain.

- Social outcomes – Elevating livability, adaptability and long-term maintenance performance.

- Governance and quality – Strengthening approval processes and quality control through offsite manufacturing.

Emerging trends and constraints in the housing ecosystem

The global housing sector is being reshaped by intensifying pressures, including persistent productivity declines, skilled labor shortages, rising material costs and widening supply–demand gaps, all of which are driving a need to transform construction practices. At the same time, decarbonization imperatives and rapid digital transformation are compelling the industry to rethink conventional delivery models. Despite this momentum, significant challenges continue that constrain adoption. There are still gaps in regulatory frameworks in many jurisdictions, creating uncertainty around approvals and long-term policy commitments, supply chain fragmentation, while concerns around durability and design flexibility influence public and private acceptance. Developers face difficulties achieving cost certainty without stable volume pipelines, and manufacturers must contend with the operational demands of automation, workforce reskilling and maintaining consistent quality control across extended supply chains. Collectively, these trends and challenges illustrate both the urgency of industrialized housing innovation and the systemic barriers that must be addressed to achieve scale.

Decarbonization imperatives and rapid digital transformation are compelling the industry to rethink conventional delivery models.

Insights from global industrialization efforts

International case studies such as Katerra, a Silicon Valley-based construction technology startup aiming to become world’s largest builder highlight both the promise and the limits of construction of industrialization. Early large-scale disruptors showed that technological ambition must be matched by strong execution, local adaptability and disciplined scaling. Models built on distributed micro-factories, repeatable product platforms and experienced delivery partners consistently outperformed fully centralized approaches, demonstrating that industrialization succeeds when it evolves incrementally and integrates seamlessly with existing industry structures.

Examples from modular programs in the UK, such as Camp Hill, Birmingham’s flagship modular build-to-rent project, as well as the global automotive, aerospace and shipbuilding industries reinforce the same message. Standardized chassis systems, digital catalogues and factory-built assemblies have accelerated delivery and improved quality, yet challenges remain around logistics, supply chain resilience and project complexity. A prime example of this is Tesla’s Model 3 and Model Y personalization — which share 75 percent of components, use software-enabled features, and are built on flexible lines that adjust automatically for different models — cutting waste, labor and assembly time while doubling output.

Other advanced manufacturing sectors, especially in cruise ships cabins, show what is achievable when precision, modularity and platform thinking are embedded at scale — offering a clear blueprint for how construction can achieve similar gains through digitized design, coordinated production and integrated assembly.

Advances in prefabricated components and engineered materials play a central role in the shift toward industrialized housing delivery. Global delivery experience demonstrates that lightweight steel frames, composite sub-assemblies, precast elements, bathroom pods and 2D panelized systems can significantly enhance performance when designed for factory-led workflows. These components enable faster installation, lower embodied carbon, reduced site waste, improved safety and greater consistency in long-term maintenance. AECOM’s former offsite construction ecosystem platform ‘Inno’ further illustrates how digital design, manufacturing intelligence and supply chain optimization can operate as an integrated system by connecting component standardization with production efficiency to support scalable, repeatable and high-quality housing delivery.

Advances in prefabricated components and engineered materials play a central role in the shift toward industrialized housing delivery.

How digital ecosystems unlock scalable housing delivery

A unified digital backbone is essential to scaling platform-based construction, linking policy, design, manufacturing, logistics, assembly and operations into a single data-driven workflow.

Digital permitting, automated compliance and blockchain certification accelerate approvals and feed directly into AI-enabled BIM, generative design and digital twin modelling, producing fabrication-ready designs optimized for performance and manufacturability.

Industry 4.0 factories then translate this intelligence into precision-built components through robotics, computer-vision quality control and automated production systems, supported by AI-driven logistics and real-time traceability. On-site, robotic assembly and IoT monitoring provide faster, safer installation with continuous performance visibility. Together, these integrated layers enable 20–30 percent cost reductions, 40–50 percent faster timelines and up to 80 percent less waste, while strengthening the potential for new export-oriented manufacturing.

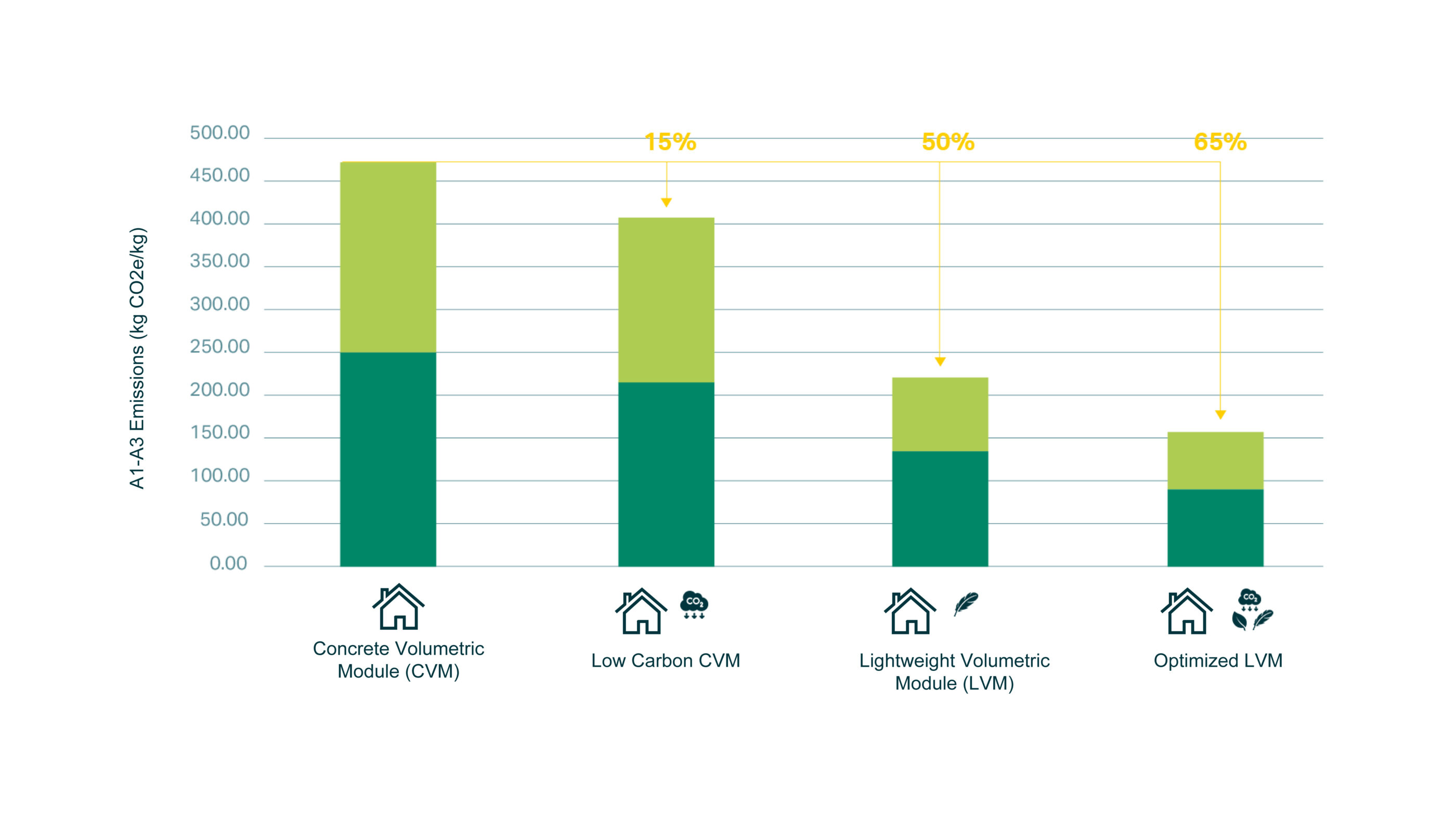

The benefits extend across sustainability and people outcomes. Industrialized systems can halve embodied carbon, reduce lifecycle energy costs and deliver more consistent safety and quality. At the same time, new technology-focused roles are created, elevating workforce skills and fostering a more collaborative, data-led construction culture.

Industrialized systems can halve embodied carbon, reduce lifecycle energy costs and deliver more consistent safety and quality.

What comes next?

To accelerate this transition, there are several practical next steps:

- Digitize and standardize design guidelines into a unified kit-of-parts catalogue.

- Adopt a tiered production model, distributing fabrication across suppliers, sub-assemblers and co-located facilities.

- Modernize permitting and certification through automated, digital-first regulatory processes.

- Invest in local micro-factories to strengthen resilience and shorten lead times.

- Expand workforce development to equip practitioners with robotics, AI, Design for Manufacture and Assembly (DfMA) and digital management skills.

With coordinated action, cities such as Hong Kong can set a new global benchmark for how they deliver high-quality, sustainable housing at scale.

Contact Marc Colella to learn more.