Deep Dive with Mark Hatcher

Our Deep Dive series features our technical experts who give you an inside look at how we are solving complex infrastructure challenges for our clients from across the world.

This week, we are highlighting a technical director from our Transportation business in the United Kingdom and Ireland, and how their team use their skills to deliver client responsive lifecycle management of bridges across the road and rail sectors.

With over 30 years’ experience and expertise in the design, construction, maintenance and demolition of structures, Mark Hatcher has been involved in the complete lifecycle of projects across the globe. He has worked on projects ranging from small community development projects in the remote mountain regions of Papua New Guinea, to multi-billion-dollar projects in major economies like the UK and Australia. Throughout his career, he has seen how structural engineering projects have the power to transform communities and change lives for the better.

In the UK, local communities are sometimes divided on the benefits that projects may bring. Mark has welcomed the increasing importance of embedding Environmental, Social and Governance (ESG) principles in all that we do, with a need to carefully balance the benefits and cost of infrastructure development.

Even where a project is agreed to be in the collective good, it is essential that we go as far as is reasonably practicable to mitigate impacts on specific groups that may be marginalized by any development. An example of a project where these factors have been challenging but immensely important to successfully meet, is AECOM’s work on the Huntingdon Railway Viaduct in Cambridgeshire, England, which is one of Mark’s career highlights.

Tell us about the Huntingdon Railway Viaduct and why the project has been a major highlight of your career. How is it delivering a better world?

The Huntingdon Railway Viaduct, once part of the A14 route, spanned the East Coast Main Line railway near Huntingdon, Cambridgeshire. It played a vital role in the UK’s transportation network, serving as a key artery for road freight and commuters. AECOM’s involvement with the viaduct began 25 years into its design life when we were appointed to manage infrastructure in National Highway’s Area 8.

During routine inspections, we identified critical structural issues, including cracking at half-joints supporting the central span and defects in post-tensioning within supporting spans.

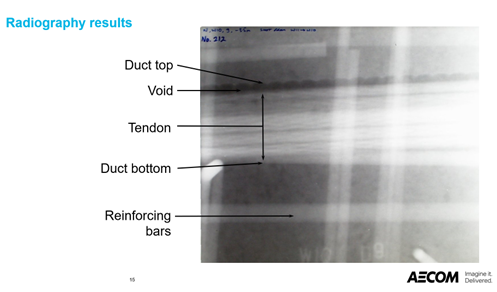

To assess the severity, we placed strain gauges to see if the cracks were increasing in size over time and used ultrasonic scans and x-ray imagery to detect damage in the post-tensioning ducts and the tendons. We then helped regrout the tendon ducts and implemented an acoustic monitoring system to continuously listen for any further damage in the tendons.

Separately, dealing with the half-joints posed a greater challenge. Conventional structural assessment methods failed, necessitating advanced, non-linear finite element modeling to predict potential failure.

To address the structural issues, we designed and supervised the installation of a series of underslung safeguarding beams that would allow load to be transferred away from the half-joints in a passive manner should they continue to ‘fail’ and thus prevent any overall collapse.

These measures enabled the viaduct to remain operational for over two decades since identifying critical defects. It saved around $50 million, reduced carbon impact, and minimized disruptions to road and rail users and residents.

AECOM’s involvement with the Huntingdon Railway Viaduct encompassed a wide range of cutting-edge solutions, preserving its functionality for over two decades while avoiding costly reconstruction and minimizing environmental disruption.”

But that wasn’t the end of the story. In 2018, a decision was made to relocate the A14 route south of Huntingdon, reducing travel times and revitalizing the local area. Our team joined the A14 Integrated Delivery Team (A14 IDT) to assist with the viaduct’s demolition.

Given the viaduct’s structural sensitivity and weaknesses, we conducted further assessments and designed temporary stabilizing brackets for a controlled demolition sequence. This decision aimed to ensure safety during the viaduct’s removal and reduce the environmental impact on the local community.

In summary, AECOM’s involvement with the Huntingdon Railway Viaduct encompassed a wide range of cutting-edge solutions, preserving its functionality for over two decades while avoiding costly reconstruction and minimizing environmental disruption. The decision to relocate the A14 route offered an opportunity for regeneration in the local area, underscoring the importance of adapting infrastructure to meet evolving needs.

What key challenges did you/your team faced while working on this project, and how did you solve them?

For me, there are two main types of challenges with complex engineering problems like this: those around people and those around the technology involved. They are often best solved by engaging a wide group of stakeholders through collaborative problem solving.

The technology side is the part that most immediately appeals to me and many of my colleagues, as this is where we get the opportunity to stretch our minds and tap into the collective experience within AECOM’s huge pool of experts.

For instance, my colleague in Glasgow, Danny Boothman, had recently undertaken some assessment and load testing on a similar structure carrying the M8 motorway in Glasgow. We capitalized on this by consulting Danny to assist with some of the more advanced finite element analysis we had undertaken for the half-joints, and this allowed us to keep the structure in service for many more years.

Other examples of our effective collaboration around cutting-edge technology include our work with testing specialists to develop X-ray and ultrasonic techniques. Indeed, even following the demolition of the viaduct, its legacy lives on as we were subsequently involved in a project to salvage part of the demolished viaduct for use for testing of even more advanced emerging technology.

However, far more often it’s the communication and human relationships that are critical to solving complex problems. Throughout our work, we endeavour to understand the needs of all stakeholders and communicate what we are looking to achieve through our deliverables whether these be our drawings, specifications or reports.

We invariably find that there is no more effective means of clarification than a meeting where everyone’s views can be heard and discussed, and this is where true understanding and synergies start to happen. For instance, at the peak of the COVID-19 pandemic and due to social distancing guidelines, we faced difficulty having the beams lifted during the bridge demolition. By working together with the client around the clock, we were able to mitigate any delays to the project and despite the challenges we faced, the project success was recognized with our collective winning of the Institution of Structural Engineers Derrington Award this year.

We invariably find that there is no more effective means of clarification than a meeting where everyone’s views can be heard and discussed, and this is where true understanding and synergies start to happen.”

How has AECOM enabled you and your teams to cultivate the expertise needed to deliver future work like this?

Our combination of local presence and global expertise, coupled with the high value we place in Diversity and Inclusion was key to our delivery of this project and many others.

As I’ve already mentioned, we consulted experts in other AECOM offices to help guide and inform how we might go about the work from the outset, such as Danny from our Glasgow team. Later, I was able to recognize the great potential in another member of our team, Ionut, who had joined us from Romania where he had undertaken some really complex stuff that put my previous input into the shade. This helped us deliver even more challenging analysis relating to the demolition phase. Ionut’s role was pivotal to us recently winning the Derrington Construction Award from the Institution of Structural Engineers.

The elevating of technical skills by our leaders as a critical component of our competitive advantage will continue to help us deliver even more challenging work in the future.