People Spotlight: Meet Ciro Viscotti

Our People Spotlight series gives you an inside look at our technical experts around the world. This week, we are highlighting a remediation expert and principal engineer from our Environment business line in Italy, providing an insight into their inspiration and work.

Ciro Viscotti joined AECOM 20 years ago as a graduate chemical engineer. Since then, he has developed his expertise in environmental engineering, remediation process and treatment technologies design, gaining wide-ranging experience for tackling various types of contaminants.

He is also involved in national networks such as the Surf Italy working group within Assoreca, to promote implementation of sustainable remediation of contaminated sites and provides ESG consultancy services related to the sustainable use of water in industrial sites. Over the past few years, Ciro has been working towards environmental management and remediation of one of the most complex PFAS contaminated sites in Italy.

What inspired you to join the industry?

I have a background in process engineering. My curiosity about the technologies of chemical and physical transformation of matter and the ambition to design something useful for the community drove me to study engineering.

Since my university days, I have always been intrigued by the idea of combining the engineering approach with the goals of environmental protection, sustainable management of resources and improved social outcomes.

I therefore decided to pursue a course of study in chemical engineering with a particular focus on the aspects of industrial safety and environmental protection.

When I joined URS in 2004, I found a dynamic and motivating environment, and the opportunity to work with an excellent technical team. I started my career as project engineer within the Environment business line, providing technical services for the conceptual, front-end engineering and final design stages of remediation systems and treatment plants. As project engineer before and as technical lead after, I had the opportunity to provide remediation services to many national and international clients and engage with leading experts and centres of excellence within the company and among key clients like Exxon, Shell and others.

Since my university days, I have always been intrigued by the idea of combining the engineering approach with the goals of environmental protection, sustainable management of resources and improved social outcomes.

I therefore decided to pursue a course of study in chemical engineering with a particular focus on the aspects of industrial safety and environmental protection.”

What is your favorite AECOM project that you’ve worked on and why?

Over the years, I have had the opportunity to work on many interesting projects. One of my recent favourites is the remediation of a former manufacturing site in Northern Italy, which produced waterproofing agents for over 50 years and contributed to the PFAS contamination of a vast portion of the aquifer, with 700 square kilometres estimated to be compromised and 350,000 citizens potentially affected by health and drinking water supply issues. This is one of the most challenging projects I have undertaken in recent times: a mixture of recalcitrant compounds, included per-polyfluoroalkyl substances (PFAS) and benzotrifluorides (BTF) have been found affecting a subsoil characterized by complex geology (alluvial deposits, marly levels and calcarenitic substrates) and seasonal variability of hydrogeological conditions.

My working group has been providing design services aimed to optimize hydraulic containment and wastewater treatment plant performance and managing the construction of physical confinement consisting of a 580-meter sheet piles wall in order to prevent clean water from entering the site, as part of the emergency measures plan for the protection of groundwater.

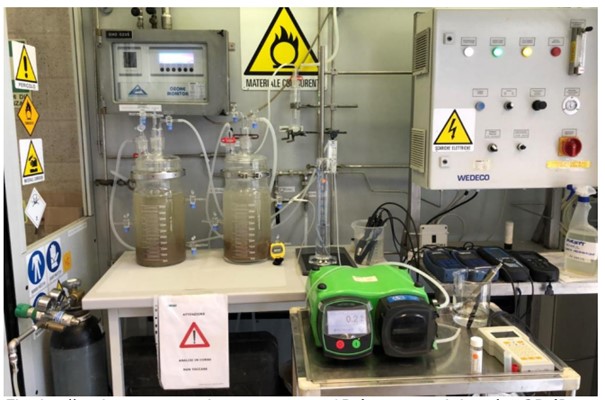

Moreover, we are carrying out bench scale tests to assess the potential of innovative treatments such as advanced oxidation processes and our DE-FLUORO™ PFAS destruction technology. This project has given us the opportunity to collaborate with our global network of experts across Europe, the U.S. and Australia, to provide viable solutions to our client.

For the remediation work for a former manufacturing site in Northern Italy, my working group has been providing design services aimed to optimize hydraulic containment and wastewater treatment plant performance, and managing the construction of physical confinement consisting of a 580-meter sheet piles wall in order to prevent clean water from entering the site, as part of the emergency measures plan for the protection of groundwater.”

Tell us a story of how your work positively impacted the community.

We have recently issued the final design for the reclamation of a historical industrial plant located within the urban area of the city of Brescia, Italy.

The industrial development after World War II led the factory to expand to its current 110,000 square meters built area. Today, entirely disused, it remains in close connection with the urban area. The industrial activity in the city — dating back to the early 1900s and mainly related to the production of caustic soda and chlorine derivatives — has heavily contaminated the soil and groundwater with inorganics, polychlorinated biphenyls and pesticides. The transport of the pollutants in groundwater and through the irrigation ditches has also caused the pollution to spread outside the industrial site.

For the past six years, I have been working on developing an integrated strategy for decommissioning and implementing remedial actions and permanent safety measures in accordance with the site redevelopment plan and the clean-up goals set by Italy’s Environmental Ministry and the local government. In a few years’ time, we aim to return part of this territory to the public for recreational use as identified by the municipal urban planning.

For the past six years, I have been working on developing an integrated strategy for decommissioning and implementing remedial actions and permanent safety measures in accordance with the site redevelopment plan and the clean-up goals set by Italy’s Environmental Ministry and the local government. In a few years’ time, we aim to return part of this territory to the public for recreational use as identified by the municipal urban planning.”

Share a piece of career advice.

Be open and curious! You can learn every day by working together with your colleagues, managers and technical experts. We have such a wide range of skills and capabilities at AECOM, that makes each project unique and interesting!