The power of smarter

Energy use is one of the biggest ongoing considerations and costs for the industrial sector. Power and energy specialist Martin Land explains how, through smart on-site power generation, and by carefully looking at energy use across facilities and sites, businesses can make their energy supply more flexible, resilient, sustainable and affordable.

Renewable energy generation technologies and emerging energy storage techniques, coupled with the drive to reduce carbon emissions, are motivating us all to develop better and smarter ways to control our energy use. What does this mean for industrial businesses and how can greater digital connectivity help?

Connected efficiencies

New process and building technologies mean factories of the future will be increasingly modular, have more flexible production and even the option to be ‘packed up’ and moved to different locations to suit new markets. New production technologies such as advances in 3D product printing will see mini factories grow as satellites from hub factories located closer to consumers.

Industry 4.0 will play a massive part in ensuring these factories stay efficient and optimised. Interconnected computer systems provide tremendous opportunities for businesses to generate, analyse and exchange production, scheduling and energy use data across systems and entire industrial businesses and supply chains. This data can be used to spot areas of opportunity for improvement or poor or inconsistent energy performance across manufacturing facilities.

Extended optimisation

The data that is now available allows businesses to manage and control their manufacturing systems much more widely. We have a system-wide approach to energy optimisation that not only considers a process but the energy that feeds it.

By considering energy use beyond just the process and facility to include infrastructure, offices, workshops, administration buildings and lorry parks, it is possible to understand the wider cost of a business’s energy use across an entire site, country or even internationally.

Detection through connection

Greater data connectivity will increase real-time traceability of how energy is used and its costs, and create decision-making opportunities with the potential to trim levels of demand.

Currently, businesses generally look at their energy costs on a daily or weekly basis. Through the use of digital technologies and processes it is possible to monitor energy costs continually and at 48 different price periods of the day; every half hour it’s possible to make a choice on what energy to use based on the price of energy at that specific time, and even sell energy to the network at times of high prices. This can really drive down wider portfolio operational costs.

Going off-grid

We believe that all new factories should look to create their own low carbon energy solutions and install energy assets paired to the capacity of the facility. This approach can provide more sustainable solutions and also helps increase energy resilience and security.

Increasing resilience and ensuring security of supply, so that essential production and process data can’t be lost, are reasons enough for businesses to consider generating their own energy, particularly through renewable assets such as wind turbines and solar power, which minimise the need for and cost of fuel.

Power protection

One of our clients, a research facility in England, was left without power for more than three days due to severe weather and flooding at an electricity substation some distance away from their premises. The unforeseen and prolonged interruption in energy supply meant they lost vast amounts of irreplaceable research data.

To mitigate the impact to future business, we’ve introduced wind turbines for local generation, and identified a combination of solar panels and battery storage so the organisation can operate as an ‘island’ away from the grid and be confident that their operations and data will not suffer the same losses again.

New markets, new locations

In locations where demand for industrial and fast-moving consumer goods is growing rapidly, such as we’re seeing in Africa, the availability of reliable power at new factories can be problematic. Smart off-grid solutions are likely to be less expensive overall and can be delivered in time, meeting production and sustainability objectives.

Smarter, more sustainable

Local, smart-enabled energy solutions include a combination of low power assets and sensory devices to adjust operation across the wider site. In the future this will extend to electric vehicles with the potential for staff and businesses to share storage across fixed assets and the vehicles, even in the facility car park.

Renewables are a big part of the future industrial energy landscape, especially in meeting sustainability targets, and when coupled with storage and combined heat and power units, intensive users will not only be doing their part for the planet but helping control their future access to affordable power.

Configuring for the future

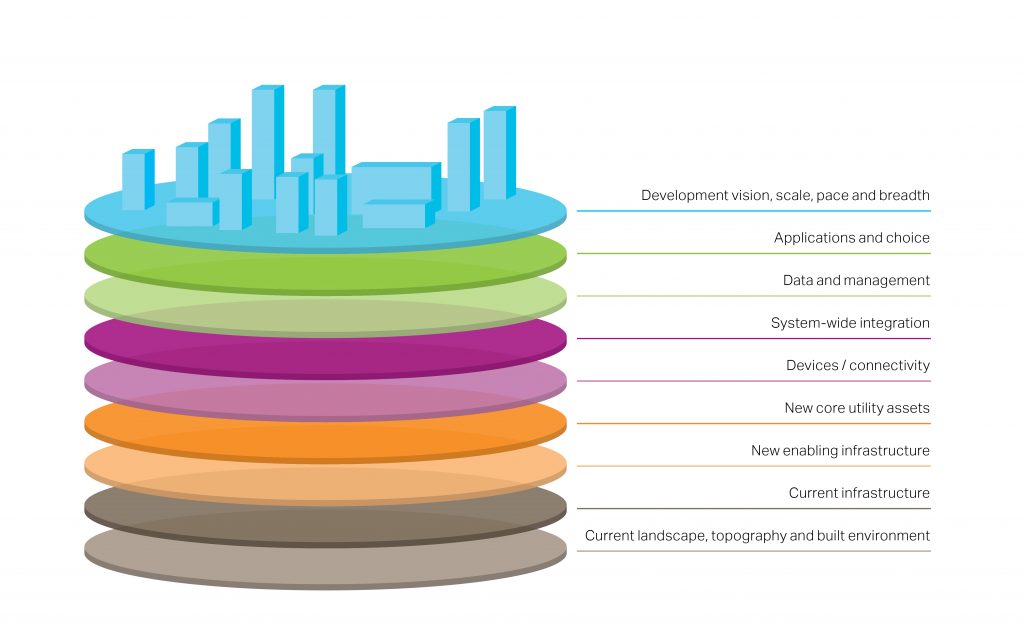

Our engineering and environmental teams partner with industrial businesses to help them manage and optimise their future energy use and utilities, including electricity, heat, chill, water, gas and emissions. Under our Energy Estate offer, we look at all aspects of our clients’ energy infrastructure and site assets and suggest ways that increased digital connectivity can drive efficiencies across their entire industrial processes and buildings.

Through this approach, it’s possible to assess how businesses can progressively harness more data and use emerging digital platforms to better integrate their energy infrastructure and site assets to drive efficiencies and make better decisions around energy generation, use and storage.

Overall, our Energy Estates approach means we can optimise our clients’ energy capacity and load requirements and reduce initial infrastructure investment and operating costs.