A time for change

Storage, logistics and how to measure success are just some of the challenges infrastructure companies face in moving towards a circular economy. Sustainability consultant Robert Spencer suggests five things that need to change to start making a circular approach work on large infrastructure schemes.

Many infrastructure organisations are committed to embedding circular economy principles into schemes because it can help address resource constraints and price fluctuations hitting infrastructure companies hard across the world, and because it’s better for the environment and future generations.

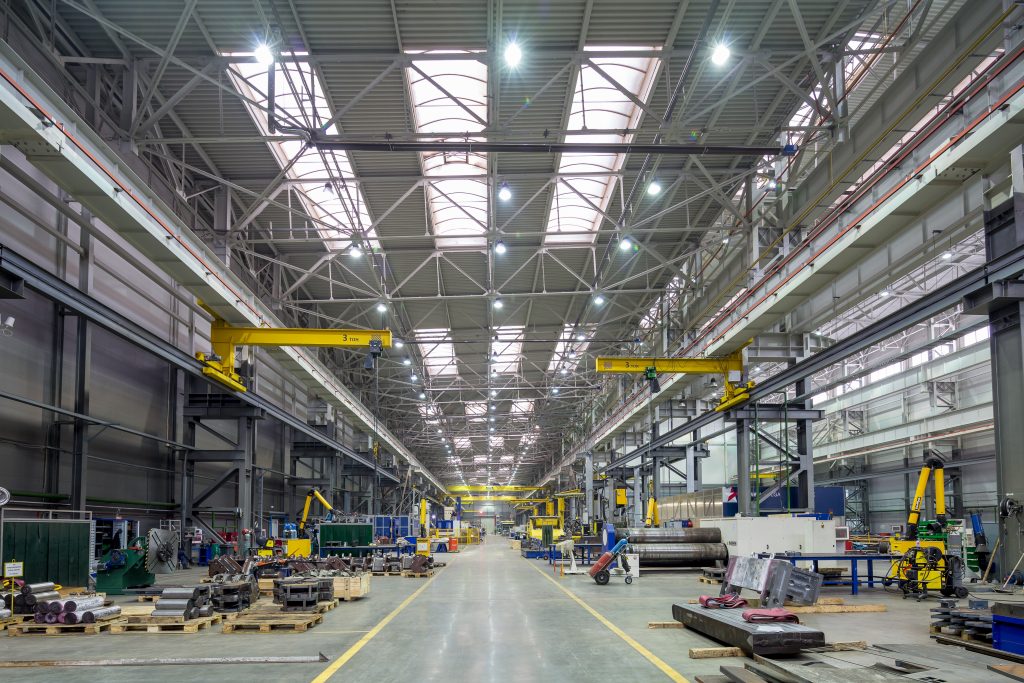

The manufacturing industry is a good one to learn from. HP Inc., for example, has produced more than three billion ink cartridges using post-consumer recycled content, such as water bottles: the recycled plastic in its Original HP ink cartridges has up to a 33 per cent smaller carbon footprint compared to virgin plastic used in the cartridges. Meanwhile RICOH imaging and electronics company remanufactures its old copiers and printers, reducing the cost of making new ones by 40 per cent, while reducing its environmental impact by 38 per cent.

But moving from the traditional ‘take, make, use, and dispose’ approach across large and highly-complex schemes to one centred on repairing, recycling, sharing and refurbishing assets and materials presents unique challenges — from how to move, store and repurpose huge amounts of materials to identifying which schemes could share the same materials and components.

High-value benefits

A circular economy keeps materials at their highest value for as long as possible by repurposing and recycling them once they have reached the end of their operational lives, creating a more sustainable materials flow and reducing supply risks and price volatility for infrastructure owners and operators.

Gas and electricity company National Grid is working with one of its suppliers to close the loop on its old overhead aluminium electricity conductor cables. The traditional approach is to send the cables off to be recycled, receiving a scrap value in return. This generic recycling model sees the material flow through the recycling value chain to enter the commodities market. Conductor suppliers then purchase aluminium on the commodities market to produce new conductors. By re-processing the aluminium cable it owns, National Grid is turning the recovered materials into new conductors with a lifespan of 40 years; reducing the amount of raw materials it needs to buy; and protecting itself from volatile metal market prices.

Why now?

Across the UK, a huge number of nationally significant infrastructure projects (NSIPs) are scheduled to be built at the same time. The UK government’s National Infrastructure Delivery Plan will see £483 billion invested in over 600 infrastructure projects and programmes from 2016 to 2021. With this comes a significant opportunity for organisations to drive the innovation and collaboration needed to embed the circular economy across projects and the industry.

Across the UK, a huge number of nationally significant infrastructure projects (NSIPs) are scheduled to be built at the same time. The UK government’s National Infrastructure Delivery Plan will see £483 billion invested in over 600 infrastructure projects and programmes from 2016 to 2021. With this comes a significant opportunity for organisations to drive the innovation and collaboration needed to embed the circular economy across projects and the industry.

What needs to change?

Drawing on conversations and ideas shared at AECOM’s circular economy breakfast briefing in March 2017, which was attended by key members of the manufacturing and infrastructure sectors, we look at five things that need to change for organisations to more easily embed circular economy principles into schemes.

1 – Map out schemes and materials

Mapping out the UK’s major infrastructure projects will make it easier for organisations to move, share and repurpose materials and assets across projects. This means investing in technologies and innovative processes that track NSIP material requirements, availability and need, such as AECOM’s Waste Harmony service which provides clients with ecologically sound and cost-effective alternatives to landfill and primary aggregate using its extensive network across the UK to match supply and demand. Through Waste Harmony, we disposed of 45,000 tonnes of spoil waste from the construction of The Pirbright Institute’s new scientific research facility by linking up with other projects that needed spoil for infilling and by organising the transfer of the waste from site. This saved Pirbright over £500,000 in construction costs and involved relocating wildlife living in the spoil heaps to adjacent conservation land.

2 – Create storage and recycling hubs

Shared storage and renewal hubs and upcycling and re-manufacturing facilities are needed to address the timing and sequencing challenges that come with re-purposing surplus materials within and between schemes. Government bodies could set up hubs strategically alongside approval of NSIPs. This will take local authority and EA cooperation and an intelligent, software-enabled marketplace to match material needs with surplus and end of life stock, and to ensure hubs run efficiently and effectively. Network Rail already has 10 materials banks across the UK, making significant improvements to its national supply chain. A UK-wide intelligent system for infrastructure materials storage could create huge cost efficiencies and positive environmental impacts.

3 – Develop a measure of success

Infrastructure companies need a way to measure their success in shifting to circular economy models. This could be a measure of the ratio between a project’s raw materials consumption and financial value to track decoupling of resource consumption from scheme budgets. The real challenge is creating a system capable of painting a UK-wide picture of performance. Organisations will need to work together to make this happen, and could draw on the new British Standard for the circular economy, which is due for publication in summer 2017.

The Major Infrastructure – Resource Optimisation Group (or MI-ROG) is already helping here. Founded by AECOM, Highways England, National Grid, Network Rail and International Synergies, MI-ROG members now include 15 infrastructure operators who share best practice and resource strategies for sustainable infrastructure delivery. Providing a collaborative space to come up with agreed circular economy measures across infrastructure operators is one of MI-ROG’s major ambitions for 2017 and onwards.

4 – Invest in more modular design

Through modular design it’s possible to create parts that can be more easily lifted out for repurposing. McKinsey’s Europe’s Circular-Economy Opportunity report says that industrial and modular processes could lower the cost of constructing buildings by 50 per cent compared with on-site traditional construction methods. One of the clever ideas to emerge from the Rio 2016 Olympics and Paralympics Games was the design of sports venues to be transformed into other uses after the Games. Described as nomadic architecture, examples included dismounting and reconfiguring the Future Arena used for handball into four local primary schools. AECOM’s role in the Rio Games spanned from creating the Olympic Park masterplan, through to concept and detailed design of most of the major venues.

5 – Invest in pathfinder projects

Organisations that invest in pathfinder projects will lead the way in developing the innovations and methods needed to move the industry forward. Scaling up pathfinder projects and collating results will show the economic benefits of taking a circular approach across different infrastructure asset classes. Building a library of pathways will open up refurbishment, upcycling and remanufacturing markets and identify which schemes share common materials and components.

The use of BIM will be critical here in providing the necessary system-wide design knowledge, just-in-time asset maintenance and refurbishment data, accurate tracking of asset components and facilitation of the increasing modularisation of infrastructure assets. This information will ensure components are delivered and swapped out for refurbishment in increasingly efficient cycles with fewer virgin raw materials required. Overall, companies that take the risk will know what works best and how to procure more efficient infrastructure delivery packages from contractors in the future.