Carbon equations for sustainable chemistry

Laboratories are energy-hungry places with demands for ventilation, power and water — all of which have environmental and cost implications. But by using thoughtful design and working with users, it is possible to design future laboratories to be more efficient, significantly reducing their energy and water use and environmental impact, writes Matthew Butler.

Laboratory buildings often require high ventilation rates to provide a safe working environment for users through the use of containment equipment that that assists scientists with their analysis.

The energy required to provide motive power and environmental control means these facilities generally consume a lot of energy leading to high net carbon emissions. At the same time, however, laboratories also provide the spaces, technical equipment and support scientists require to produce the sustainable technologies needed to secure a successful low carbon future.

The GlaxoSmithKline (GSK) Carbon Neutral Laboratories for Sustainable Chemistry building, owned by the University of Nottingham, was developed to enable this low-carbon ambition. The design of the building itself facilitated the development of low-energy strategies for its operation, with ongoing monitoring of its performance providing valuable lessons to improve the way it and other future buildings operate. Possibly most importantly, the work of the scientists who both use and are inspired by the building, is helping to make our low carbon future a reality.

To achieve the very low energy consumption necessary to target Net Zero Carbon status, the GSK Carbon Neutral Laboratories for Sustainable Chemistry had to be designed to save energy wherever possible.

Drawing on our experience and knowledge of how laboratory buildings actually work, we reviewed all of the building services systems and identified where we could improve them from conventional practice to provide greater energy efficiency.

The building has now been in use for three years. AECOM has been monitoring the actual power and water consumption as well as obtaining feedback from the users about how the building performs for them. This process has generated valuable insights into how future laboratories can be designed to be more efficient.

In all types of buildings, especially large energy consumers such as laboratories, the most significant opportunities for savings are found by identifying where energy is being consumed unnecessarily.

Five ways to save energy

1/ Off means off

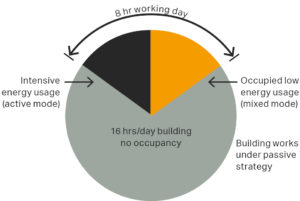

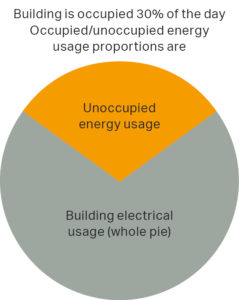

Normal working hours only occupy one-third of a working day and less than one-quarter of the hours in a whole year. The most significant energy savings can be achieved, therefore, by ensuring that, wherever possible, the heating, ventilation and air conditioning (HVAC) systems are off, or set back as much as possible. Controls, with the ability to detect when spaces are occupied and respond to required demands, are essential for this. User behaviour is also important; identifying the agreed working hours can allow the simple setback of systems to achieve significant energy savings.

2/ Understand actual loads

Generic metrics like building regulation calculations allow for a relative comparison between buildings. Simplifications in the modelling, however, do not accurately reflect the benefits of different HVAC strategies within a laboratory environment.

Our experience shows that, for laboratory buildings, the actual total energy consumption is typically twice that predicted by building regulations calculations. As a result, it is crucial that decisions about servicing strategies for laboratories are based on optimising energy-consumption reductions for the actual building, not just improving the building regulations calculation.

3/ Decentralise systems

Large centralised air handling systems for ventilating and cooling laboratories can provide a relatively easy solution. However, the resulting compromise in control of the central systems and energy losses in distribution can lead to significant energy use. Localising ventilation and cooling systems to specific laboratories allows air to be supplied at just the right temperature and flowrate to suit the specific requirements. This helps generate significant savings from free cooling from fresh air as well as reduced distribution losses.

4/ Decrease water consumption

Historically, laboratories have been very large consumers of water. By providing the right infrastructure, such as closed loop cooling systems for condensers, we can facilitate improvements in scientific working practices that result in significant reductions in actual water consumption. This reduction in actual consumption is not generally reflected in standard design allowances for storage and distribution design.

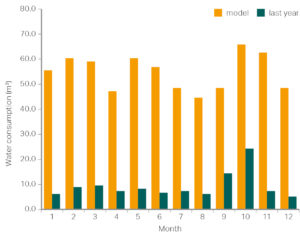

Figure 2 below shows the actual water consumption for the GSK Carbon Neutral Laboratories for Sustainable Chemistry compared with the modelled demand based on standard design metrics. By designing to these actual consumption figures, we can cut the size of storage, distribution and hot water generation facilities and save capital costs, limiting the risk of stagnation in oversized water systems and saving energy from standing losses in oversized hot water systems.

5/ Smart metering and ongoing monitoring

Providing the best possible building does not end at hand over. Even with expert design input, you can not anticipate every possible operating scenario. In addition, the new building’s users may need support, guidance and encouragement to use the facilities in the most efficient way. Smart metering is an important tool that can help with this, enabling the monitoring of energy and water consumption throughout the building.

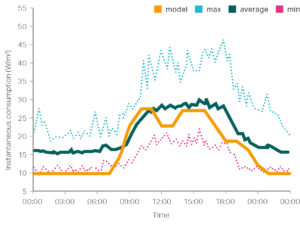

Within the GSK Carbon Neutral Laboratories for Sustainable Chemistry, we have been monitoring power consumption in the laboratories and feeding the results back to the users about how their habits are impacting building performance, particularly, where equipment is being left on overnight.

Monitoring the building’s HVAC systems’ fuel and power consumption is helping us to understand how the controls are actually interacting with the building so that we can identify where they can be tweaked to support and promote the best performance from the building.

Neutral Laboratories for Sustainable Chemistry

A fresh approach

Designing laboratories in the same way they have always been designed results in poor-performing buildings. By using experience gained from previous buildings and better understanding the specific requirements of individual users, we can design buildings that are more efficient and better able to respond to the specific user requirements.

Monitoring utility demands and profiles will optimise supporting engineering infrastructure and, more widely, help us secure the low carbon future we need.