Keeping tabs on waste

Green growth refers to growth that is resource-efficient, clean, and resilient. It is a commitment to pursue development in a more sustainable manner from the start, rather than the more conventional and costly model of ‘grow first, clean up later’. A reinforced commitment to green growth will ensure that Malaysia’s precious environment and natural endowment are conserved and protected for present and future generations. (11th Malaysia Plan)

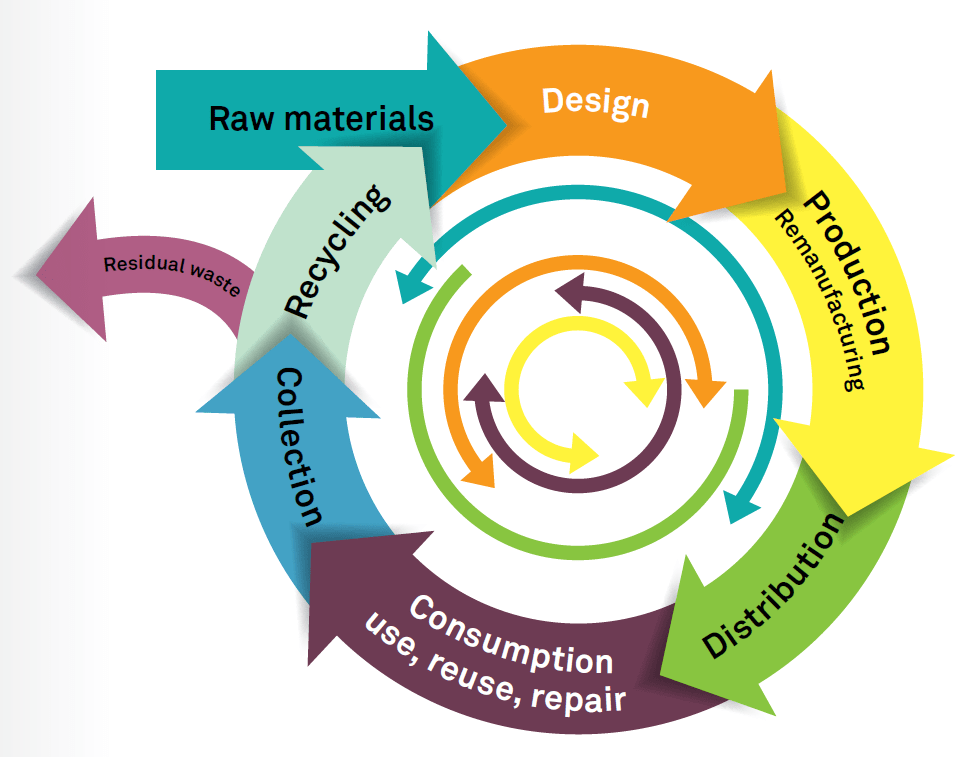

Malaysia’s waste management strategy is to manage waste holistically based on a life cycle approach (11th Malaysia Plan, 2015). The parties involved include the National Solid Waste Management Department, the Solid Waste Management and Public Cleansing Corporation, the Atomic Energy Licensing Board, Department of Agriculture, Department of Environment and Minerals and Geoscience Department and National Water Services Commission.

Aimed at achieving a goal of 22% household recycling rate by 2020, the Government has introduced the following initiatives:

- Waste separation at source for households to be implemented in selected states starting September 2015 and rolled out to other states subsequently during the 11th Plan.

- An investment in waste recycling and recovery to reduce dependency of industries on natural resources. Waste becomes a valuable resource – either converted to energy (e.g. bio mass and food waste for power generation) or used as an input for other products.

These initiatives should be private sector driven to ensure long-term financial viability of the projects so that industries see the value of waste as a source of energy or inputs for their processes. According to a waste survey conducted by the Department of National Solid Waste Management, the quantities of solid waste (excluding construction waste) generated in Malaysia comprise:

|

Sector |

Metric tonnes per day (tpd) |

|

Household |

21,627 |

|

Commercial & Industrial |

2,279 |

|

Industrial |

9,224 |

|

Total |

33,130 |

Roughly converted, each person in Malaysia generates 1.17 kg per day. The following table shows the breakdown of waste by type:

|

Tonnes per day |

% composition |

|

|

Food waste |

11,141 |

33.6% |

|

Garden |

1,392 |

4.2% |

|

Other |

206 |

0.6% |

|

Paper |

5,437 |

16.4% |

|

Plastics |

6,985 |

21.1% |

|

Glass |

900 |

2.7% |

|

Metals |

1,399 |

4.2% |

|

E-waste |

33 |

0.1% |

|

Batteries |

25 |

0.1% |

|

Hazardous |

358 |

1.1% |

|

Diapers |

2,641 |

8.0% |

|

Textiles |

875 |

2.6% |

|

Rubber |

399 |

1.2% |

|

Leather |

139 |

0.4% |

|

Wood |

521 |

1.6% |

|

Others |

670 |

2.0% |

|

Total |

33,130 |

100.0% |

Based on the waste survey, it is estimated that the overall recycling rate for Malaysia is 9.6%. The highest rates are for metals (47.6%), paper (34.4%), plastics (19.1%) and glass (19.7%). Hence, the amount of waste diverted currently from landfill is 3,174 tonnes per day based on 9.6% of the solid total waste generated. Considering the aim of achieving 22% solid waste recycling rate, the government needs to double the current amount to be absorbed back into society.

Can cities unlock the resource potential of food waste?

In the real world, this does not seem to be case. According to the Food and Agriculture Organization, about one-third of all food produced worldwide, worth around US$1 trillion, gets lost or wasted in food production and consumption systems. Every year, consumers in industrialized countries waste almost as much food as the entire net food production of sub-Saharan Africa (222 million vs. 230 million tons). At the end of the food chain, food waste is defined as the food lost during retail activities and final consumption and relates more to behaviour. In Europe and North America, consumers throw away 95 -115 kg per year, while in industrialized Asia, the “throw away” amounts to 80 kg per capita per year.

How do we turn food waste into a resource? There are various means of doing this.

Composting – organic matter that has been decomposed and recycled as a fertilizer and soil amendment

Animal feed – the feeding of food scraps to animals is historically the most common way of dealing with household food waste. Animals turn a third of ingested food into meat or dairy products

Industrial – Used cooking oil is a common waste that can be turned into biodiesel

Energy – anaerobic digestion is the process by which organic matter such as animal or food waste is broken down in the absence of oxygen to produce biogas and biofertiliser

But to convert food waste into a resource, there are challenges to be overcome along the value chain. At the sorting stage, unfamiliarity among the public with how to handle food waste means extra manpower will be needed for sorting. During collection, temporary storage of food waste, if not properly carried out, can generate odour and hygiene problems. Although scale is favoured to make recycling cost-effective, additional administrative effort is often needed to collect for high-density and high-rise buildings. Transportation effort and costs further arise when bringing waste from collection points to treatment facilities. These can be as high as two-thirds of the total operational costs. Post-treatment and maintaining quality control of the product is important as incomplete decomposition or product that is contaminated cannot be used e.g. unfinished compost would not be suitable for gardening. Lastly, there must be sufficient market capacity to absorb large amounts of the final recycled product e.g. local needs from agricultural and landscaping use.

Many cities are looking at food waste recycling strategies within urban settings. San Francisco city has instated a “zero waste” target by 2020 and has made the sorting and composting of food waste mandatory. The city has a compost facility 89 kilometers east in Vacaville which supplies compost to the Napa and Sonoma wineries. In Sweden, Malmö city has also imposed mandatory sorting of household food waste whereby citizens recycle their food waste through waste grinders, vacuum systems or paper bags in garbage bins. The waste is anaerobically broken down to produce biogas to fuel city buses, garbage trucks, taxis and cars. The Adelaide city council in Australia provides Green Organics bins for residents for food scraps and peels, meat scraps and bones, teabags and coffee grounds, egg shells, dairy products, hair, shredded paper and tissues. The bins are a way of making recycling more localised and with the abundance of urban gardens, Adelaide has high food waste recycling achievements of up to 90%. Compost and mulch produced by this method is certified to Australian Standards AS4454 which is suitable for public, landscaping supply yards, landscapers and agricultural growers.

In Malaysia, the Kuala Lumpur Centre for Sustainable Innovation is working on the design and establishment of an innovative food waste recycling scheme in a 1,000 resident public housing complex located in Kepong, in the Greater Kuala Lumpur area. Food waste will be collected from individual owners’ apartments, processed into compost on-site and used to nurture an urban farm for the residents. The innovation of the waste recycling scheme is that it eliminates transportation costs, which is usually the largest component of operating costs for this type of business. If successful, this scheme can be easily replicated across other communities in urban areas across Malaysia. In a survey of residents within the complex, findings showed that:

- Almost 70% cooked at home meaning that regular grocery shopping (85%) occurs once a week or more. In other word, there is regular supply of food materials coming into the complex.

- When asked why does food go to waste, almost 60% state that this due to spoilage, which is consistent with the local preference for fresh food.

- Roughly 45% of the households sort their food waste but just 55% are prepared to take this waste to the local collection point.

- Typical of urban dwellers in a high rise setting, more than 80% of those surveyed would not buy compost whether from food waste or other sources. This indicates the need for an urban garden as the outlet for the recycled food waste.

So what can we learn? There is a need to address behaviour change on food waste sorting and use of recycled products through public education. Mandatory sorting is needed (as demonstrated by San Francisco and Malmö). Specific collection arrangements for high-rise buildings should be implemented e.g. designated food waste collection bins should be provided; there is potential to incorporate pneumatic chute disposal systems in newly designed buildings. Some cities have instated waste charging mechanisms and at the same time offered economic incentives for households to sort food waste, for which they will be charged less. Food waste recycling operators must have viable business models, which mean that robust secondary markets for the finished products are vital.

This short paper was prepared for the CleanEnviro Summit Singapore 2016 .

The circular economy

The common definition of the circular economy is one where waste generated by one party can be converted into a useful resource for another party. This description of waste embraces not just solid materials but also other resources such as energy and water. By applying this principle, a closed loop is created, regenerating resources rather than the need to exploit new ones. The opposite of a circular economy is a linear economy.

A common example of the circular economy would be that of a tenant on an industrial complex using the waste by-products of another tenant as an input into his or her process. A slightly more complex example would be recycling bodies working either in-house or externally with producers and supply chains to take used products from users in exchange for new ones and reusing the used products either back into the original product stream or disassembling them for recycling elsewhere. Producers themselves can lead and own such initiatives by implementing ‘take back’ policies to encourage users to return used products to the manufacturing process.

The circular economy tends to exist internally within specific sectors. But the key to a true circular economy is to link up separate sectors so that spent resources from primary markets can be fed back into the same primary markets or into secondary markets. In shaping the circular economy, there are three main aspects to be considered: remanufactured goods; reconditioned goods; and secondary use goods.

Remanufactured goods refer to goods that enter the market as new but with re-used components such as glass and wiring. Reconditioned goods are those that retain the original body but with new internal components such as upgraded circuits and chips. Secondary use materials are materials from disintegrated assemblies that are recycled into low end applications like road surfaces, plastic fillers or wood chips.

Reuse or Recycle?

There is also a distinction between re-use and recycling. The former occurs when used products are converted into resources and put back into the original product, which will then be sold as a remanufactured or reconditioned good. If the used product is used as a resource for secondary use i.e. lower-value recycled products like road surfaces, plastic fillers or wood chips, it is considered to be a recycled product. This commonly comes from dissembled used items.

On a global level, a circular economy could help enable developing countries to industrialize. For developed countries the circular economy may increase wellbeing and reduce vulnerability to resource price shocks without placing unsustainable pressure on natural resources and breaching environmental limits. The Ellen MacArthur Foundation estimates that if the European Union manufacturing sector adopted circular economy business models, it could realize net materials cost savings worth up to US$630 billion per year by 2025.

Can We Do It?

As in the case of many countries, the private sector provides the bulk of investment in innovation. Hence the policies set by governments are critical in accelerating the time it takes for breakthroughs in materials science and product design. Currently, companies are still reluctant to make the transition to circular economy practice due to a perceived lack of expected returns. The Ellen MacArthur Foundation has argued that the most profitable opportunities lie in products with a medium life span – longer than a single use but short enough for reuse and remanufacturing to be attractive. Barriers in applying the circular economy include:

-Lock-in to resource-intensive infrastructure and development models – the physical infrastructure of production, consumption and trade is highly geared to once-through manufacturing models.

– Political obstacles to putting an appropriate price on resource use – subsidies that encourage excessive use of resources will need to be removed and all ‘externalities’ incorporated into the price of resources and energy.

– High up-front costs – in the short term, there are significant up-front investment costs and risks for businesses – e.g. retooling machines, relocating whole factories, building new distribution and logistics arrangements and retraining staff.

– Complex international supply chains – supply chains have to be reorganized so that information and material flow can facilitate reuse and remanufacturing.

– Lack of consumer enthusiasm – consumers need to understand and value what the concept represents; a product certification or labeling system may be needed.

– Challenges for company-to-company cooperation – incorporating circular economy practices can require multiple companies to adjust their operations with potentially large transaction costs and delays in negotiating with partner companies.

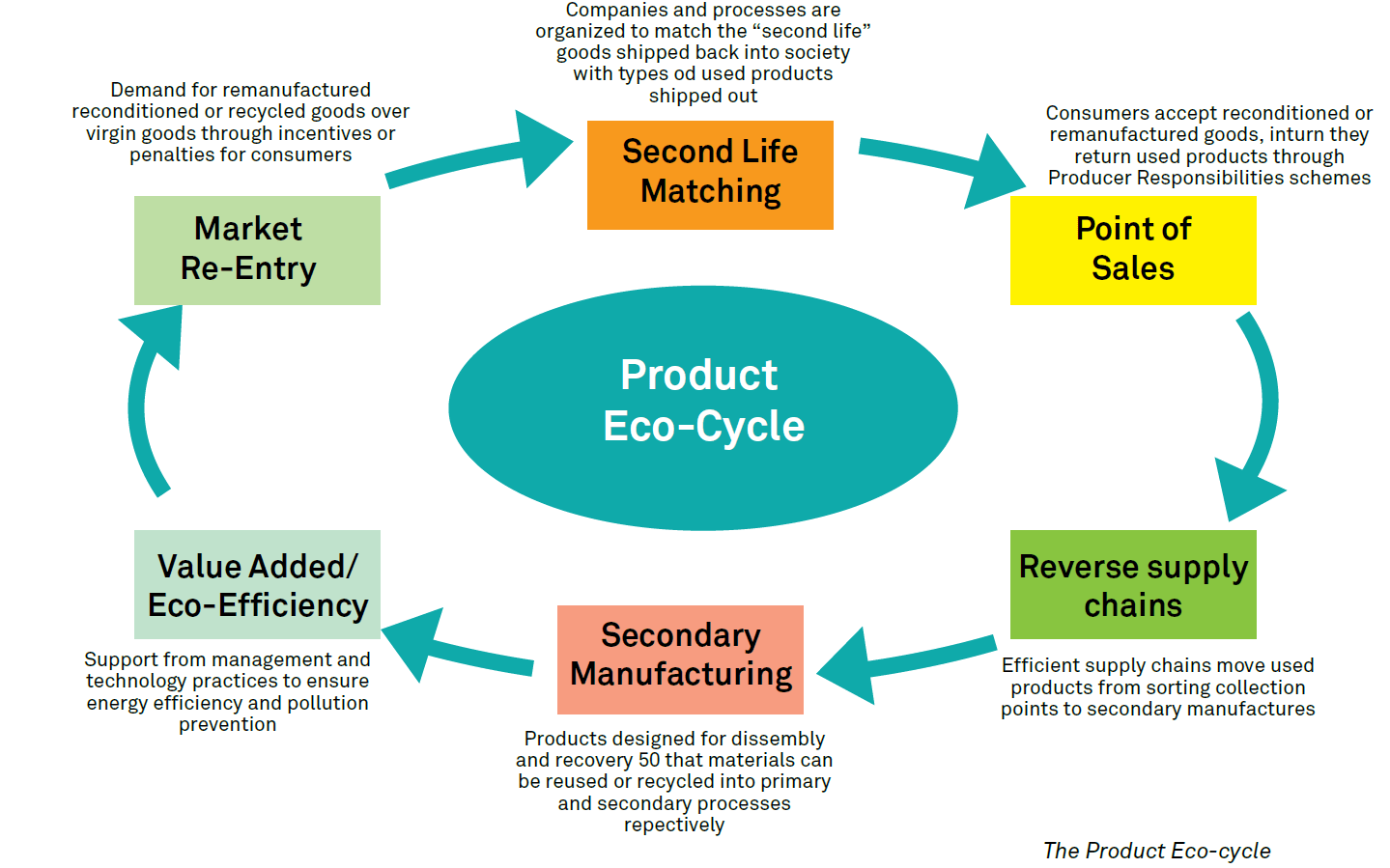

The Product Eco-Cycle

To apply the circular economy to Malaysia, the Product Eco-cycle model is proposed. The model traces the path of products across the entire life cycle from raw materials to post consumer use.

Compared to other models such as producer responsibility, producer take back and design for environment (DfE), the product eco-cycle is not intended to replace them but rather integrate the separate models into one holistic approach for specific products. The main difference is that collaborative partnerships between manufacturers, wholesalers and retailers are emphasized otherwise the individual elements of the product eco-cycle will not work in isolation of each other. Savings through economies of scale and the returns from recycling can thus be shared amongst all the players, as well as being further invested into the facilities and services necessary for the product eco-cycle.

In theory, it would be possible to apply the circular economy in a compact urban centre where collection and sorting systems operate and companies collaborate closely with one another. In practice, one particular example of the product eco-cycle is in photocopiers where there are dedicated resources to achieve this goal. As photocopiers are a specialized niche, there is no reason why other specialized niches like mobile phones and computers cannot adopt this approach.

Materials should be separated into biological and non-biological categories. Taking the latter first, non-biological products like metals are already in the circular economy as there is intrinsic value in the materials. But other materials like plastics, glass and paper are usually part of one-trip products which are discarded after use. A paradigm shift is needed to re-design products so that such materials can be retained in the original shape and form as the products and can be reused either through reconditioning or remanufacturing. The materials will have more value as the product is more attractive in intact form instead of being dismantled. One way to retain the value of a product is to ‘rent’ it out so that the consumer returns the product when no longer in use. Glass bottles are an example where the bottles can be reused many times if designed properly. Biological products, usually food, are difficult, if not impossible to re-use. The best uses for biological products are aerobic and anaerobic digestion. Using the byproducts of the broken down items as nutrient for urban farming, in a sense, it closes the loop of lifecycle management. This provides opportunities for landscape designers and engineers to create ‘green’ urban infrastructure and space for growing crops.

Companies need to look beyond short-term objectives and make business investments in retooling machines, building new distribution and logistics arrangements as well as retraining staff. The starting point would be for products with a medium life span – longer than a single use but short enough for reuse and remanufacturing. In doing so, company-to-company cooperation must be established. Also governments must remove subsidies that encourage excessive use of resources, enforce sorting and separation to create the right material streams for the circular economy to work, licence the recycling industry to remove ‘rogue’ traders, provide land and resources for the private sector to set up the value chains needed for circular economy practices, educate the public on the need for managing resource and establish product certification or labeling systems so that consumers understand and value what the concept represents. For the consumer, the product eco-cycle represents a change in lifestyles, away from purchasing one-trip product to value-add reuse. This would encourage a reversion to old fashioned values of ‘saving and conservation’ which will make for a more sustainable economy in the long run.

|

Product Eco-cycle stage |

Business Opportunities |

|

‘Second Life’ |

Testing laboratories to verify that the performance of ‘second life’ products meet adequate performance standards. In particular, the role of standards testing laboratories is essential to ensure that second life products and materials are just as good as the original ones. |

|

Point of sale |

Enterprise Resource Planning (ERP) and systems experts to plan and forecast sales |

|

Reverse supply chains |

Logistics companies to sort, collect and return the post-consumer products back to manufacturers. |

|

Secondary manufacturing |

Process engineers and product designers to design machine tooling and products, respectively. Material technologists to identify better materials, which can be introduced into the manufacturing process. |

|

The recycling sector |

Consultants to introduce eco-efficiency and socially responsible as well as innovative practices. |

|

For market re-entry |

Marketing and branding companies to promote consumer demand for remanufactured and reconditioned goods. |

The key to unlocking the potential of the circular economy lies its ability to link up separate parts of the value chain. Such a linkage allows spent resources from primary markets to feed back into the same primary production chains. The value chain should be a preference rather than turning to lower value secondary markets.

Conclusion

The Product Eco-cycle model is proposed as a way to apply the circular economy to Malaysia. The key to unlocking the potential of the circular economy lies its ability to link up separate parts of the value chain. Such a linkage allows spent resources from primary markets to feed back into the same primary production chains. The value chain should be a preference rather than turning to lower value secondary markets.

Companies need to look beyond short-term objectives and make business investments in retooling machines, building new distribution and logistics arrangements as well as retraining staff. The starting point should be for products with a medium life span – longer than a single use but short enough for reuse and remanufacturing. In doing so, company-to-company cooperation must be established.

Also governments must:

- Remove subsidies that encourage excessive use of resources.

- Enforce sorting and separation to create the right material streams for the circular economy to work.

- License the recycling industry to remove ‘rogue’ traders.

- Provide land and resources for the private sector to set up the value chains needed for circular economy practices.

- Educate the public on the need for managing resources.

- Establish product certification or labeling systems so that consumers understand and value what the concept represents.

For the consumer, the Product Eco-Cycle represents a reversal in lifestyle away from purchasing one-trip product to value-add reuse. This would encourage a reversion to old fashioned values of ‘saving and conservation’ which will make Malaysia a more sustainable economy in the long run.