Mine water management: cleaner mines, cleaner energy

The global transition toward clean energy technologies has triggered a rapid increase in demand for minerals and raw materials that are required by the renewable energy industry. The challenge today is extracting these essential resources without harming the environment in the process.

One of the greatest hurdles — and potential opportunities — is the management and prevention of harmful discharge into surface and groundwater. Smarter mine water management is a crucial piece of this puzzle. Lucy Pugh, our global industrial water practice lead, explores how mine water can be treated and reused to reduce the impact on the local environment.

Increased demand means increased responsibility

Growth in renewable energy, electricity networks, electric vehicles (EVs) and battery storage technologies is driving an ever-greater need for minerals. Elements such as copper, cobalt, nickel and lithium are, and will continue to be, in high demand. The World Bank predicts that demand for copper alone, largely driven by these low carbon technologies, will increase by 50 percent in the next 20 years.

As the mining industry ramps up operations to supply these elements, their environmental practices face increasing scrutiny. Water management plays a crucial role in mining — it’s essential for extraction, washing, sorting minerals, dust suppression and slurry transport. Effective water management is key to a company’s operational efficiency, sustainability and compliance with current regulatory requirements.

Drivers for change

Mining operations impact local water sources in several ways, including acid rock drainage from mine waste, residual chemicals present in wastewater, management of tailings (a by-product of the mining process) and the diversion of watercourses on the surface or underground.

Since the middle of the last century, attitudes about how we use water in mining have changed considerably for the better. This has been driven by several factors:

1. Water scarcity. In dry regions like the Australian outback, mines must reuse water to protect the region’s ecology and maintain operations.

2. Continuously evolving regulations. Water management rules vary by country. Regulations change as new research reveals new risks. Mandates respond based on new information, such as the hazards of constituents like selenium in mining water.

3. Environment and social value. Alongside other heavy industries, mining companies have a responsibility to society to minimize their environmental impact. Moreover, their performance on these issues can influence shareholder confidence and business viability.

4. Cost. Recycling wastewater lowers treatment expenses and reduces the need for expensive freshwater supplies, especially in water-scarce regions.

There is also the potential cost (financial and reputational) of contravening regulations, both for discharge and water extraction. In recent years, regulators have issued numerous fines for breaching water licenses – including a Chilean copper mine which received a US$8.2 million fine in 2022 for exceeding its permitted extraction limits, while a Canadian mine was fined CA$60 million for polluting watercourses in 2021.

A two-fold approach

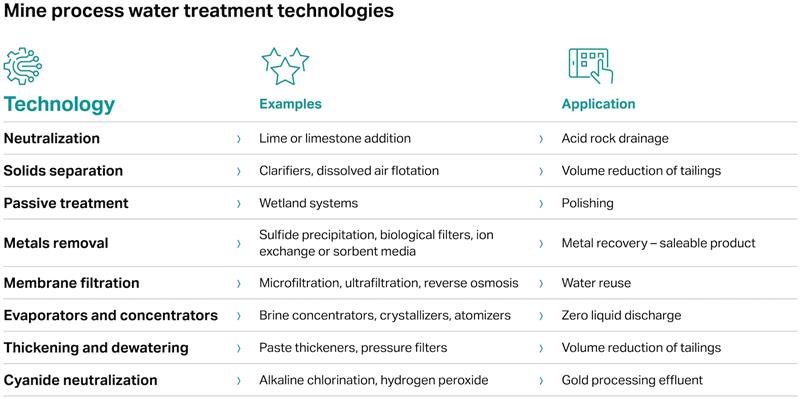

Water management challenges are unique to every mine. They vary based on local regulations, geography, water tables and the materials being extracted. However, management can broadly fall into two main approaches, each with their own pros and cons:

1. Treatment for water discharge. This process can be expensive. For instance, cyanide used to leach gold from ore must be removed from wastewater. Mines have traditionally used costly oxidation or ultraviolet light technology for treatment. The good news is that new technologies, such as SART (sulfidization, acidification, recycling, thickening), reduce operating costs and environmental liabilities by recovering cyanide for reuse.

2. Treatment for water reuse. This strategy may involve capturing excess water from early processing stages and repurposing it for later steps, such as using polishing water to clean equipment. However, reuse is only possible if operators understand how added chemicals behave in the water and react throughout the mining process.

Successful examples of mine water management

Solar glass mine — Manitoba, Canada

A mining company intended to extract sand for the glass used in solar panels; however, the mine was in an environmentally sensitive area with an indigenous community and important fishing grounds nearby. In response, the company committed to zero water discharges by using only mechanical treatment processes, avoiding chemicals. This approach allowed the reuse of 100 percent of the available process water, minimizing the need for additional water.

Base metals mine — Flin Flon, Manitoba, Canada

Nearly a century old, storm water and spring melt would collect in the Canadian mine, which became contaminated by minerals from the mine tailings. The contaminated water needed to be treated before being discharged into the watercourse, involving chemically intensive processes.

Initially, the site owners planned to neutralize the tailings to cut long-term costs. Instead, they discovered a way to reclaim the valuable minerals. They adopted a solution that uses a series of chemical extractions and physical separation technologies including flotation, countercurrent thickening and dewatering. After extracting the residual minerals, dewatered tailings will be placed in an impoundment area that are capped at end-of-life with no further surface water treatment expected.

What does the future hold?

As demand for key materials used in clean energy technologies grows, so does the need for smarter mine water management. Future strategies are likely to focus on reuse as water becomes scarcer through climate change, and regulations for discharge become tighter. AI modeling and real-time sampling will also enable operators to reduce the quantity of chemical reagents while still maximizing extraction — decreasing costs, improving environmental discharge and increasing revenue. There will be a trend toward natural treatment, especially in large legacy mines where traditional chemical methods are prohibitively expensive.

Mining operations will always be connected with the economics and implications of water management. By embracing innovative water management strategies, the mining industry can transform its environmental footprint, avoiding harmful discharge and proving that critical resource extraction and responsible stewardship can go hand in hand.

If you’d like to find out more about mine water management, please check out our industrial water page.