Offsite construction: unlocking a thriving and sustainable construction industry

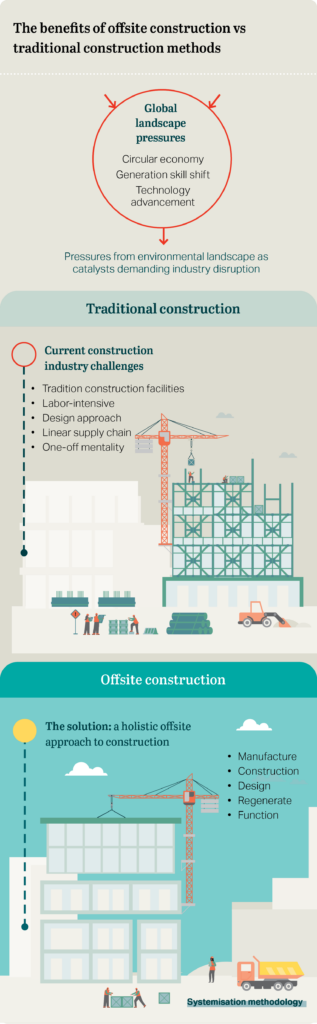

Modern methods of construction (MMC), widely recognised as offsite construction, will be integral to the longevity of our buildings, the creation of a thriving and sustainable construction industry, and a resilient future for all. This article explores the benefits of offsite construction and why increased policy is essential to improving the procurement process, encouraging innovation, and driving widespread uptake.

Pressure is mounting to address the construction industry’s role in limiting climate change. In Australia, we finally recognise that offsite construction could be one of the most effective construction methodologies for sustainable development and may help solve systemic industry challenges such as fragmentation, skills shortages, and antiquated methods of construction.

Offsite construction offers significant environmental, quality and safety benefits compared to conventional construction methodologies, but what are the barriers to widespread adoption?

Realising the benefit: a whole-of-life construction process

The construction industry is on the precipice of radical change. Offsite construction provides an opportunity for a traditional building process to evolve into industrialised construction. We can design building components for production in a manufacturing environment, creating an ideal platform for smarter design to harness new technologies that will shape and fundamentally change construction as we know it today.

We can disrupt industry norms by integrating Artificial Intelligence within smart production facilities, using 3D printing for intricate components, and applying biomimicry principles to create responsive and restorative products that eliminate waste, which will provide the efficiencies needed to keep up with growing demand. Fundamentally, offsite construction is more sustainable than traditional construction. With new technologies in practice, we will see higher quality construction, greater precision and less waste during manufacture, improved safety outcomes, and faster delivery.

Offsite construction requires us to consider the entire building lifecycle and unlock value even at the end of a building’s useful life. Each stage is intimately interrelated – from manufacture, assembly, and operation to disassembly for the recycling and reuse of components.

The end of a building’s life should be as important as the start, and we must ensure each component is selected and designed for reuse and easy detachment.

Currently, our industry applies a ‘one-off’ mentality towards the construction of assets, meaning an expensive, labour-intensive, traditional approach from design through to construction. Typically, we reinvent the wheel, designing every project from scratch. We would increase efficiency by using designed-for-use components if we applied offsite construction methodologies. For example, when designing a hospital, we need bathroom pods, Mechanical, Electrical & Plumbing (MEP) riser modules, prefabricated air handling units, MEP horizontal modules, and prefabricated structural components. We can save time and money by customising existing component designs, manufacturing offsite, and integrating onsite.

For the most part, buildings should no longer be perceived as bespoke but rather as mass customisation of integrated, systemised products designed for automation, while maintaining aesthetics and identity through a creative, adaptive envelope.

An industry game changer

![]()

Time to transform, together

The pandemic provided a reset button to realign construction methodologies and help reverse years of environmental degradation, giving us a vision of an alternative, cleaner world. It’s never been a more critical time to adopt new technology and embrace new practices like offsite construction. However, to realise this vision, industry, government, and academia must work together to engineer the basic building blocks for long-term resilience. Our government must provide leadership by reforming procurement policies and frameworks, committing to a project pipeline that encourages investment in new technologies, and providing whole-of-life performance benchmarking with the industry. Industry and academia must also collaborate to drive innovation and technological advancement. We must identify skill gaps, develop the appropriate future workforce, and create opportunities to upskill the existing workforce.

The demands of our growing population are greater than the current pool of skilled manual labour workers can deliver. As an industry, we need to adopt modern methods of construction to alleviate the pressure on our workforce. The immediate investment and incentivisation to upskill workers in the technologies of tomorrow will help meet demand while simultaneously achieving sustainability requirements.

Success will ultimately rely on collaboration between stakeholders, underpinned by a common goal to address the climate crisis and ensure a resilient future.

The cost of MMC is a challenge – as a relatively new method, MMC is not always the cheapest option. However, looking only at immediate monetary spending when considering value is short-sighted. We need to step back and assess the tangible benefits of MMC, such as higher quality components and less wastage during manufacturing. The intangible benefits such as improved safety outcomes with more regulation and less onsite work, regional economic growth, and new industry growth are yet to be measured and used as project benchmarks.

With the right support, we can make the desperately needed jump to MMC and reap the advantages for generations.