On track for better asset management

It’s one thing being able to collect data, but quite another to interpret and optimize its use.

When one of the world’s largest iron ore producers wanted to introduce a more accurate and scientific approach to its rail network maintenance program, it looked for a digital solution with powerful analytical capabilities.

For a rail network covering hundreds of miles through remote landscapes, reliability in transporting minerals is essential to the smooth running of the company’s operations. In the past, assessments for new works have been carried out manually and based largely on the subjective views of track inspectors and engineers.

Providing the key to unlocking the rich seams of data being collected from the network is a new tool called a transport analysis and modeling platform (TAMP). TAMP provides data analytics using track geometry and survey data for identifying when to carry out upgrades and maintenance.

Combining and collating

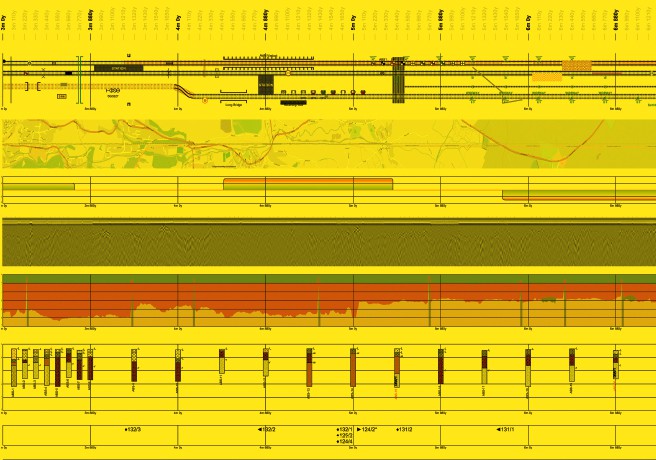

Building the new web-based system started with entering historic information into the database including details about track assets, construction, mapping and track geometry data. This was then combined with survey findings such as information from core samples of the track foundations and ground-penetrating radar data to assess track-bed construction. The radar survey alone can generate terabytes worth of data. In addition, there is information about the types of traffic using the network. Once data is combined and collated, a common geo-spatial referencing system is applied and then a graphical display makes it possible to browse the entire system. Maintenance teams can log on wherever there is an internet connection and view, manage and analyze the data using the simple interface. It is one of the first track assessment systems to provide access via the internet for maintenance teams and is the very first to use track geometry data to assist with analyzing earthwork failure.

“Among the most important data for any rail operator is track geometry” says David Kite, AECOM’s project manager and principal engineer, based in Nottingham, U.K. “Being able to easily process and visualize track geometry data helps us to understand deterioration rates and maintenance improvement, which in turn reveals facts about the performance of the track. Many hours of manual assessment can now be accomplished in seconds.”

Data highlights

TAMP receives gigabytes of track geometry data comprised of billions of rows of data, each with a dozen data streams.

Decades of track maintenance records and other datasets were input to understand track condition.

AECOM’s surveys generate terabytes of ground-penetrating radar data and perform time and frequency domain analysis to interpret and present this data.

The system is able to digest thousands of kilometres of track data and perform deterioration rate analysis to understand track performance.

Multiple datasets are correlated to understand interdependencies and produce track performance models.