Net zero heroes: helping the NHS achieve its carbon reduction goals

At the frontline of the coronavirus health crisis, the National Health Service has established itself as the nation’s hero. Now it has another ambition: to become the world’s first ‘net zero’ national health service. As it embarks on what Health Secretary Matt Hancock calls the “biggest, boldest, hospital building programme in a generation,” AECOM’s Adam Bradshaw says building structures will be key to achieving this goal.

The much anticipated publication in October of the NHS Delivering a ‘Net Zero’ National Health Service comes as the NHS embarks on a long-term programme of investment in health infrastructure. With £3.7 billon funding to build 40 new hospitals, delivering on the net zero commitment is going to require a new approach.

Net zero means reducing the carbon emissions associated with a building’s usage and construction to zero or below. Thanks to the huge and varied demands required of them, hospitals have a large carbon footprint from both construction and operation, although modern design and a decarbonised grid look set to radically reduce operational emissions in future. To achieve the NHS objective, hospital trusts should look closely at the building structure, which our analysis shows has the potential to be most impactful when it comes to reducing embodied carbon demands.

As NHS Chief Executive Simon Stevens makes clear, the climate emergency is also a health emergency. Leading by example, the NHS – which is responsible for around 4 percent of the nation’s carbon emissions – has set out a clear objective of reaching carbon neutrality by 2040.

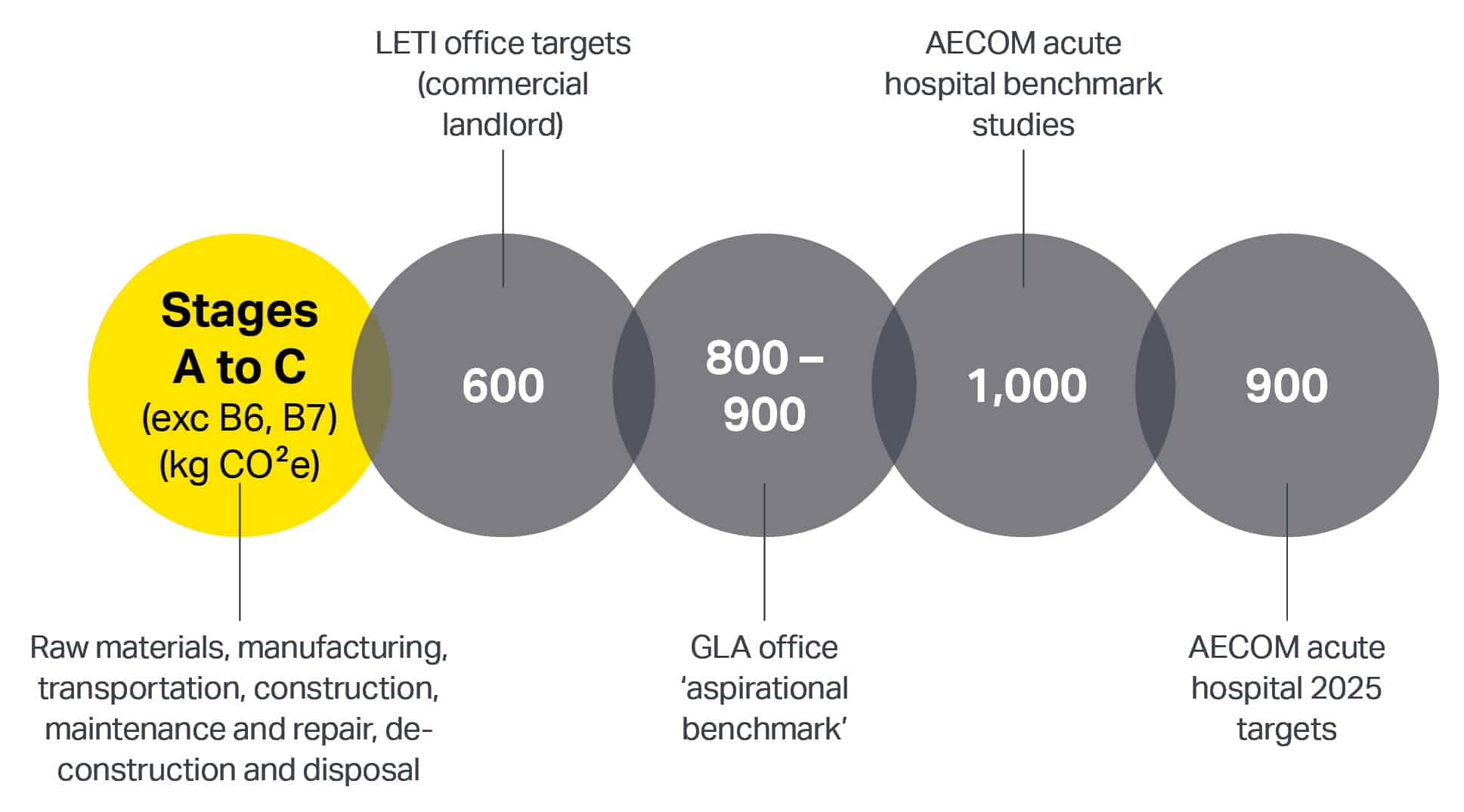

Official targets for embodied carbon have not yet been set for new hospitals, but we have compiled what we think those targets might look like by using targets for Greater London Authority office buildings, those put forward by the London Energy Transformation Initiative, combined with AECOM benchmark studies of both office buildings and recent completed hospitals. Figure 1 demonstrates the range of ‘do minimum’ and ‘aspirational’ targets for both GLA and AECOM benchmark studies. This has enabled us to set our own targets as shown.

To inform net zero strategies, the UK Green Building Council and LETI have compiled a set of building guidelines, to which AECOM has contributed. In addition to these considerations, hospitals have specific requirements that deserve careful consideration.

On an individual scale, hospitals contain a variety of departments ranging from administration through to theatres and imaging. Each space has different structural design requirements which need to be addressed: from space requirements influencing grid spacing, to floor loading requirements and vibration limits. The buildings also need to accommodate complex equipment and mechanical, electrical and public health (MEP) routing requirements, with high space demands for services. Medical equipment such as MRI scanners are heavy and have stringent vibration criteria.

To address the specific and changing nature of healthcare provision, hospitals require adaptable and flexible solutions – as the rapid re-purposing of spaces during the coronavirus crisis highlighted. In the future, hospital buildings and facilities must be designed to respond to multiple and fast changing health situations, with space for new technologies.

From operational energy efficiency to the question of whether to build new or refurbish, there are many considerations for hospital trusts to consider. In this article, we are going to focus on what our own analysis has shown to have the most impact on reducing embodied carbon emissions: the building structure.

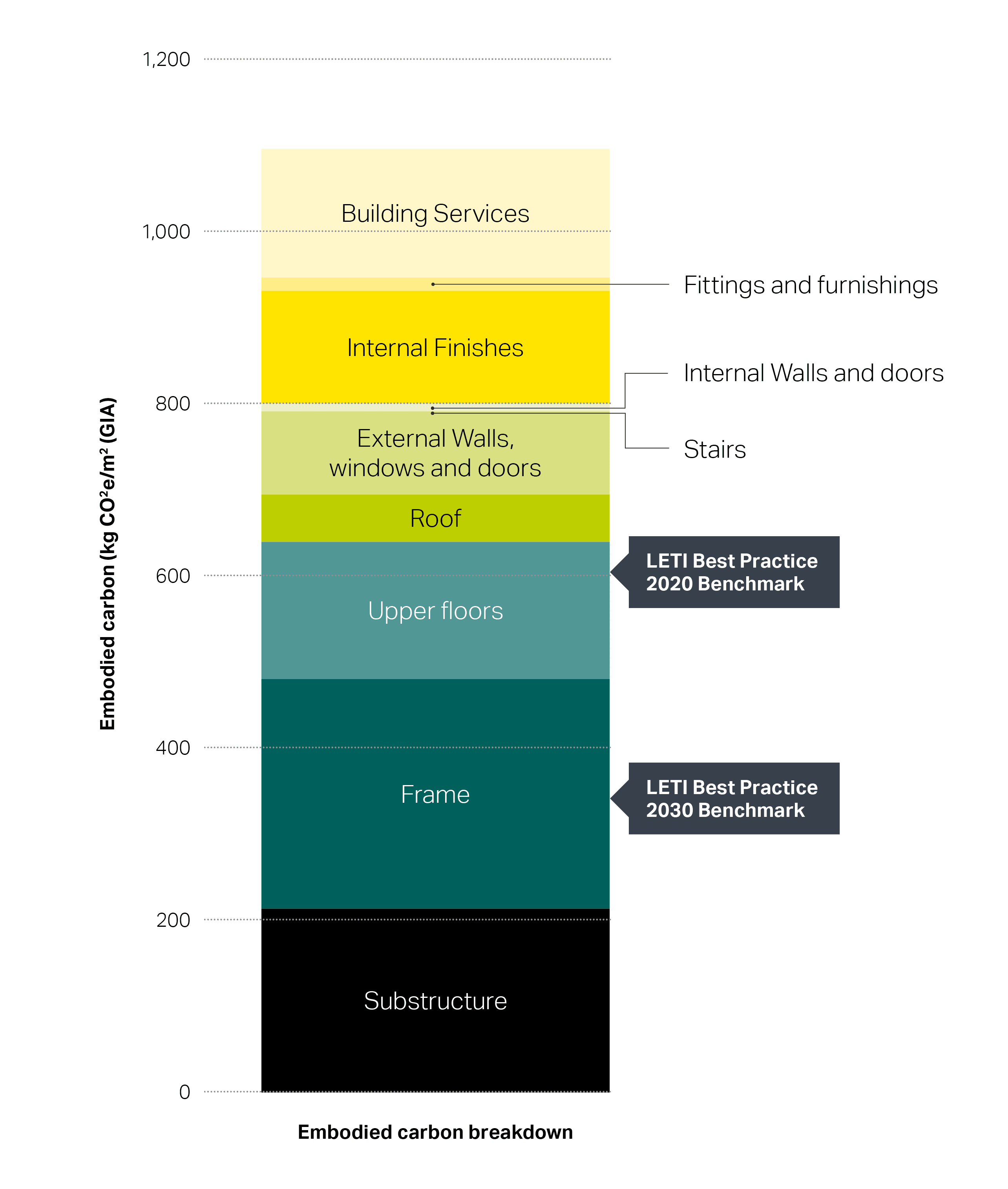

Thanks to experience delivering carbon efficient buildings such the GSK Carbon Neutral Laboratories for Sustainable Chemistry, the world’s first carbon neutral lab, and the LEED Platinum facility at NASA Ames Research Center in California, AECOM has been building up a library of carbon data relating to a building’s structure. Figure 2 shows that half of the embodied carbon of a typical office building is due to the structure. When it comes to hospitals, the percentages are similar, despite the unique challenges placed on such buildings.

Three considerations for net zero hospital design

To reduce the carbon footprint of a building structure, three considerations are key: design, materials choice and offsite manufacture and assembly.

1/ Design

Three broad principles will help achieve the best energy efficient outcomes from design:

a) A pragmatic approach

To rationalise material use and reduce carbon content throughout the building, the following lean engineering practices will help:

- providing regular grids,

- maximising the repeatability of structural elements,

- designing to standard component size as much as possible,

- maximising pre-fabrication potential,

- limiting the structural spans,

- avoiding irregular shapes and structural complexities such as transfers.

Reducing the use of basements can also have significant savings. AECOM benchmark studies have shown that 20 per cent of embodied carbon can be found within the substructure. This figure rises exponentially with the inclusion of basements.

b) Avoid over-specification

Like the human body, the different elements of a building are inter-connected, and prescribing a specific outcome for one variable can put pressure on other variables. The key is achieving a balance between flexibility requirements, which require additional functionality, and efficient design. This requires input from NHS estate managers, clinical planners and the design team as a whole to first establish flexible criteria and the strategies to implement these.

c) Applying circular economy principles

Design focused on eliminating waste and re-using resources can increase building life span as well as incorporating flexible structural arrangements. From the outset, consideration should be given to what happens at the end of a building’s life, designing for dismantle and re-use.

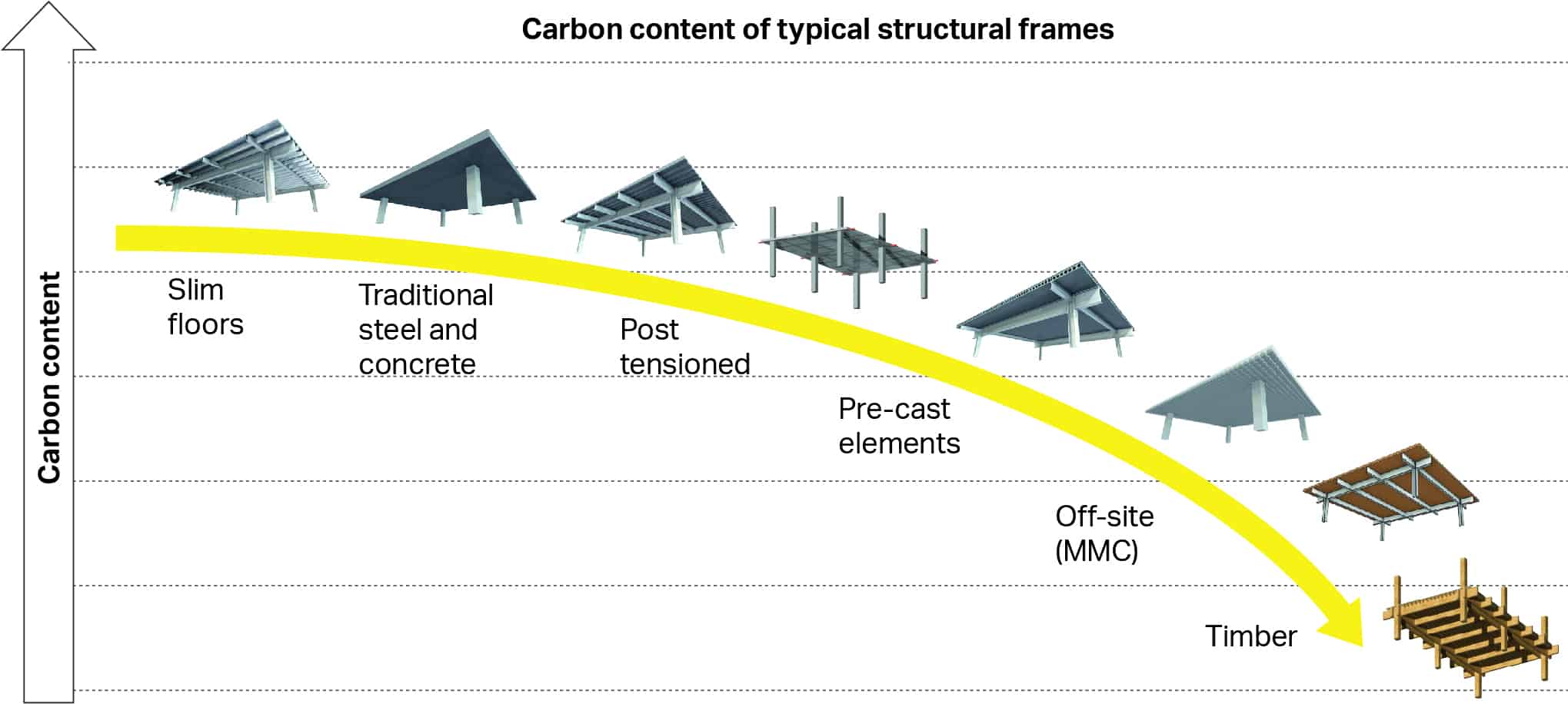

2/ Materials choice

The choice of materials used in construction has the potential to impact embodied carbon significantly, and exploring the most appropriate material should be considered from the outset. As Figure 3 shows, using sustainable materials such as timber, and reducing high carbon content materials such as swapping cement with replacement materials can make a huge impact.

Developing designs around the chosen material will maximise carbon savings. AECOM has developed bespoke tools to define materials choice by enabling rapid prototyping of early stage options and reporting against performance criteria including carbon content. Along with our carbon calculators and advanced analysis tools we can then maximise carbon savings throughout the design development of the building.

A timber hospital?

The standalone winner in terms of carbon content is timber, which could even be carbon negative. However, following the Grenfell Tower fire tragedy in 2017, the government banned the use of structural timber along with other combustible materials in external walls of buildings over 18 metres. The ban has had wider implications on the desire to adopt structural timber and insurance difficulties. This shouldn’t preclude timber as a viable structural frame option for hospitals, but while nervousness remains regarding its use in the whole structure, consideration should be given to ancillary structures or selected structural elements.

3/ Design for offsite manufacture (Modern Methods of Construction/MMC)

To support the modernisation of the construction sector, off-site production is being actively encouraged by the government, whose five central departments have adopted a ‘presumption in favour of offsite construction’ for public buildings. The NHS looks to be following suit with a requirement to explain how , when applying for funding from government.

Through efficient energy usage in manufacturing techniques and the reduction in material usage and waste, offsite production. Evidence collected so far suggests that construction waste and site CO2 emissions can be more than halved through a DfMA approach compared with traditional practices. It can take many forms, from constructing individual structural elements (steel, concrete or timber) through to full building modules. Taking full advantage of these benefits requires structural engineers to adopt the design principles stated above from the outset.

The world’s first ‘net zero’ national health service

With NHS net zero carbon hospital standards due to be set in Spring 2021, the business case for the planned new hospitals will need to demonstrate the energy strategies to meet them. The challenge is to not only meet these emerging requirements, but to pre-empt them. To be sustainable, the new projects should be built to serve current and future generations.

Tools and processes to deliver on these aspirations include rapid prototyping and optimisation software used from inception, through to advanced bespoke carbon calculators giving BIM linked real time carbon assessments through the detailed design phases. The planned 40 hospitals should be net zero heroes, carbon exemplars that set the trend for future NHS buildings and infrastructure.