The requirements revolution in rail is here. Time to get on board.

The private sector supply chain has a critical role to play in helping Network Rail meet its objectives for Control Period 7. You told us that a focus on scope and requirements is where we can have significant impact. Here’s what effective requirements management looks like to us, writes Steven Murdoch, AECOM’s Rail Lead across UK and Ireland.

Last year, Mark Harper, the Secretary of State for Transport, made clear his expectations of the UK rail industry. Accelerated delivery by more efficient means is top of the agenda to deliver for the public purse, passengers and the planet.

The private sector supply chain has a critical role to play in helping Network Rail meet these objectives. So, how can we work collaboratively to overcome blockers that are currently impacting the drive towards ever more efficient delivery?

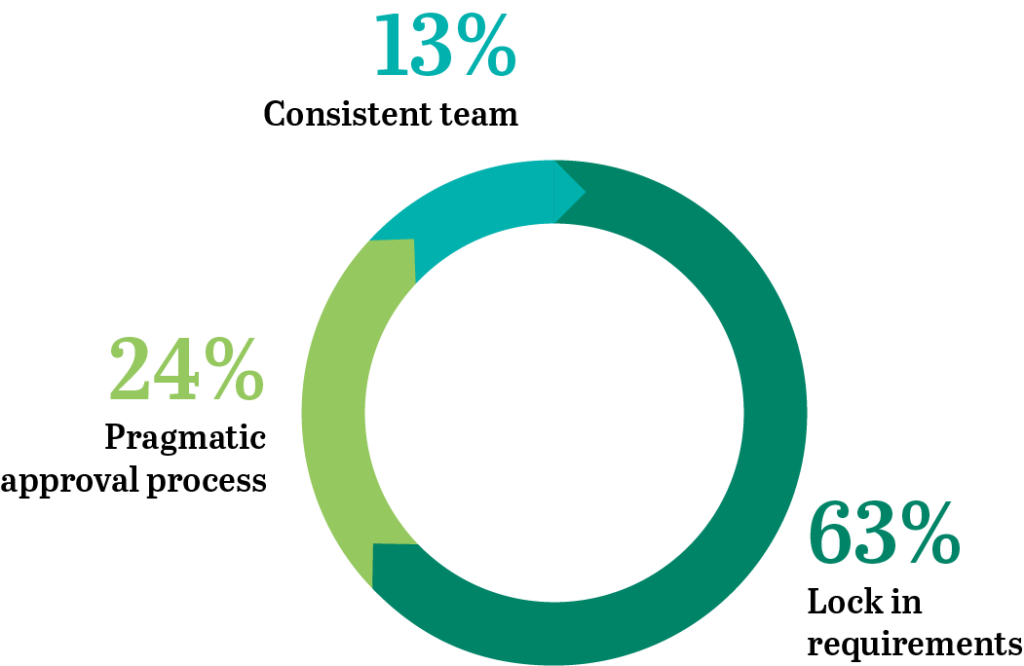

We put that question to colleagues and peers in a LinkedIn poll ahead of two major rail conferences in 2022. The results showed a clear direction of travel.

Above: A graph illustrating the results from the LinkedIn poll ‘How can the rail industry overcome blockers to efficiency and collaboration?’

An overwhelming 63 per cent agreed that a focus on scope and requirements is where we can have the most impact.

But how do we do that? As trusted partners to the UK rail industry, here’s what effective requirements management looks like to us.

Interrogate and challenge

The governance change from GRIP to PACE is mandating the drive for scope clarity, and the private sector supply chain must step up, challenge the norm and focus on outcomes that benefit customers of the railway, both passengers and freight.

Here at AECOM, Minimum Viable Product (MVP) is our guiding principle. However, you can’t successfully design for MVP unless you relentlessly interrogate the brief and scope.

The earlier this is done in the project lifecycle the better. There are times when it’s hard to resist the urge to move straight into construction (especially when there is pressure to deliver), but the benefits for passengers (in the form of less disruption) and for the planet (less resources used) are strong drivers for change. These include reduced disruption for passengers, and a decrease in resources used. Naturally, money goes further, too – another important incentive in the context of a finite funding envelope.

Put simply, an empowered supply chain has the confidence to step back, interrogate the requirements and be vocal in driving ever more efficient approaches to project delivery.

Outcome-driven requirements are the future

To be empowered to generate lean and value-driven solutions, we would like to see a move away from over-prescriptive requirements. If the brief is over-subscribed, then opportunities for efficiency become limited and innovation stalls. In addition, there is a real risk to project budgets if requirements are over-prescriptive.

That’s why we think that outcome-driven requirements are the future. Instead of designing to budget, we need to be delivering outcomes to budget.

Considering the abovementioned point, it is much easier to interrogate the brief and scope if the outcomes — and budgets — are clearly defined.

Collaboration and trust drive value

As my colleague Conor Linnell demonstrates here, collaboration and efficiency go hand-in-hand. That relationship certainly extends to effective requirements management.

Collaborative models and frameworks that contractually embed a one-team approach like the Southern Rail Systems Alliance provide a non-competitive environment and ‘safe space’ for all parties to interrogate the requirements to generate value-driven, innovative solutions that meet the wider outcomes.

Trust can, of course, be fostered outside of an alliancing model. We are working with Scotland’s Railway Supply Chain partners such as BAM Nuttall and Siemens on a range of projects — including the recently-opened Inverness Airport Station — where a great working relationship and collaborative mindset are empowering us to de-risk, simplify and streamline the design and construction of schemes such as East Linton station (see case study below).

Doing things differently

Ultimately, we must do things differently if we are to embed a culture of productivity and efficiency within the UK rail industry.

Change is not easy — and we must challenge ourselves not to revert to type, especially in pressured situations. It’s important as a collective that we build on the lessons learned from Control Period 6 and acknowledge that there will be bumps in the road to more efficient delivery. Ultimately, delivering the best for the planet as well as customers — both passengers and freight — is what drives us.

Interrogating the scope at East Linton Station

The excellent working relationship between Network Rail, AECOM and contractor BAM Nuttall has been critical in identifying ways to improve the design and construction of the new two-platform station on the East Coast Main Line at East Linton in Scotland.

Through continued interrogation of the requirements, the team was able to:

- streamline the telecoms work by challenging the need to reroute cables

- challenge design norms and de-risk the overhead line equipment (OLE) work

- understand the loading requirements on the lighter, more streamlined platform construction, working with the specialist piling contractor to simplify the piling method and reduce the number of piles

- work with the steelwork fabricator to optimise modules for fabrication and installation during the GRIP5 design phase – rather than after it.

With construction currently ongoing, the team continue to collaborate with the wider supply chain to ensure that delivery remains on track, splitting out packages of work and managing risk to ensure a steady flow of components needed to install the new station.

Click here to read more about our work in East Linton.