When zero is more than nothing

When it comes to science buildings, reducing energy consumption and increasing environmental sustainability remains as challenging as ever says sustainable engineering expert Alan Fox.

Science buildings are energy hungry to build and to run. And while the holistic approach to sustainability is designed to capture the impact of a project on occupants and environment, it is still usually seen as focussed on energy consumption. The government’s approach to ‘zero carbon by 2019’ goes some way to introducing balance. Until we really take into account the operation of science buildings, then the true aspirations of achieving zero carbon will not happen.

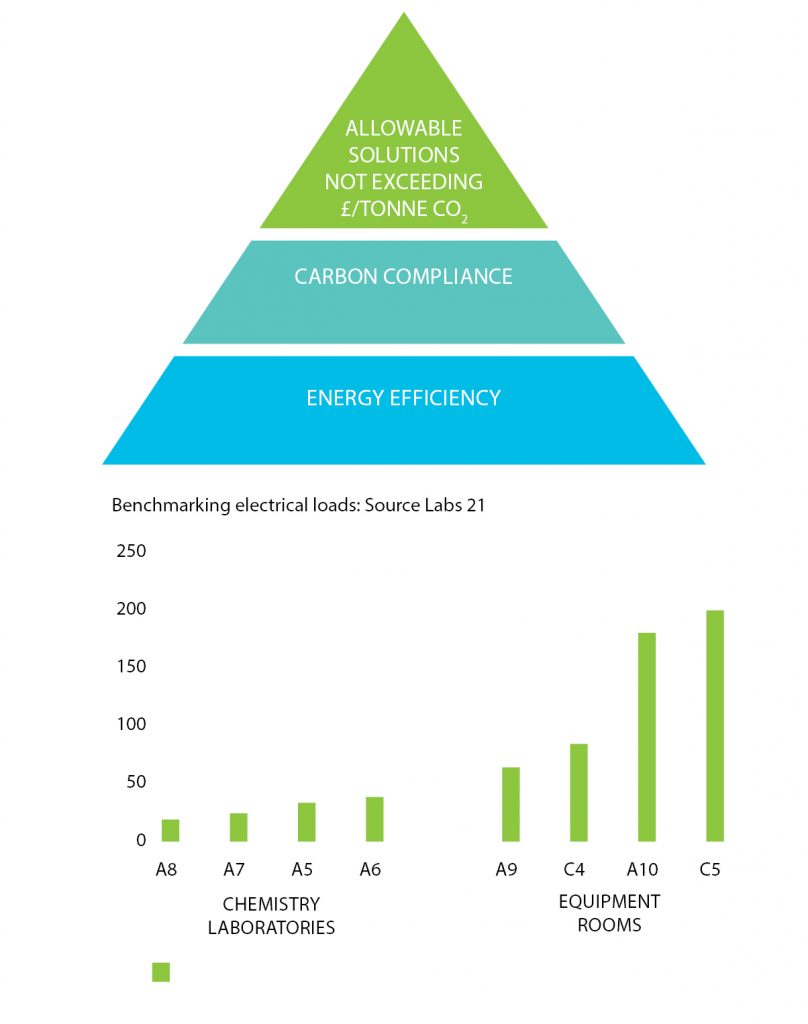

The government approach to ‘zero carbon by 2019’ has a three-tier hierarchy:

- Meeting minimum energy efficiency parameters in terms of the building design and equipment.

- Mitigating predicted carbon emissions from regulated

energy uses via on-site or

near-site solutions. - Using allowable off-site solutions where on-site solutions are not feasible.

Mind the gap

This approach is a partial step to realising our obligation to carbon reductions. The process is based on metrics from standard calculation methodologies that provide like-for-like comparison with notional buildings. However, there is a danger of merely compliance engineering to meet regulatory or planning conditions. This will not address the root cause of our ever-increasing consumption and our surprise at the performance gap between design and operation.

This approach is a partial step to realising our obligation to carbon reductions. The process is based on metrics from standard calculation methodologies that provide like-for-like comparison with notional buildings. However, there is a danger of merely compliance engineering to meet regulatory or planning conditions. This will not address the root cause of our ever-increasing consumption and our surprise at the performance gap between design and operation.

This performance gap is easily explained; the energy model used for Part L compliance is a tool that provides like-for-like comparison, but it does not reflect the actual use of the building. Standard usage templates of space types which appear in the calculations often fall short of the actual operational use of a space. Without the ability to change standard input data, the gap between design and actual performance widens. Notwithstanding this, many science buildings will require the application of low or zero-carbon technologies to achieve building regulation compliance.

The considerable investment required in photovoltaics, heat pumps or combined heat and power solutions often causes cost-plan concern in the design stage or operational concern in use. It may, however, be the case that insufficient investment is being provided as we know that buildings will consume more energy.

While consideration can be given to benchmarks of actual operational performance and contributions of the low- or zero‑carbon technologies, these can be fraught with complexity as rarely are two buildings the same in functional requirements.

We need to reassess our approach to design and our operational behaviours. This should start once the functional scientific brief is defined and at a point where the team can take time to ask some ‘what if?’ questions. These may typically be:

- What happens if I turn it off? — Can I turn off ventilation systems, pumped systems or equipment at the end of the day?

- What happens if I let the environmental conditions ‘float’? —Where do I need ‘close environmental control’ 24/7?

- What happens if I have a failure?

- Can I do it differently? — Can I use a ventilated enclosure instead of a fume cupboard?

- Can I be more efficient with the use of space?

- Am I transferring inefficient laboratory equipment or do I have a procurement strategy in place that considers the energy rating of new equipment?

- Do I know how I use my energy at the moment and what would I like to monitor in future?

- Are my mixing zones creating a collaborative scientific buzz among staff?

- And finally, what does sustainability mean to me and will I have a framework to maintain sustainable objectives after occupancy?

This last question should be put to all stakeholders to establish whether propriety sustainability benchmarking tools such as BREEAM or LEED should be applied or even supplemented with additional criteria or a new sustainability framework created specially for the project.

At AECOM we believe that the delivery of a sustainable building is only a success if it can be operated, maintained and monitored effectively. To achieve this, the appropriate level of metering, monitoring and performance testing has to be provided. A sustainable building can then only move from a construction stage to an operational stage when its controls and monitoring have been effectively proven, and there is an ongoing commitment for measurement and monitoring in place.

The use of benchmarking can provide a degree of confidence in relation to design proposals; it is widely used in setting electrical loads for differing space types early in the design stage. However, more meaningful data may be obtained by understanding certain metrics such as:

- Occupants/m²

- Hours of operation

- Metering breakdown

- Ventilation rates l/s/m²

- Electrical base load W/m²

Case Study : UK’s first carbon-neutral lab

The newly completed GSK Carbon Neutral Laboratory for Sustainable Chemistry at the University of Nottingham is a completely carbon-neutral structure, the first of its kind in the UK. Part funded by GlaxoSmithKline, the building serves as a hub to catalyse new collaborations with industry. The centre is unique in the UK, not only in its design, but also in its focus on world-leading research activity in sustainable chemistry that aims for the highest ‘clean and green’ standards to minimise environmental impact and ensure that the new chemistry developed is energy and resource efficient, and sustainable. The building is constructed from natural materials to reduce and offset embodied energy. Meanwhile, the energy required to run the laboratory is met by renewable sources with a combination of photovoltaic panels on the roof and heat and power generated from a sustainable biofuel. The building services throughout have been designed to minimise energy use wherever possible, including an exemplar naturally ventilated laboratory. Excess energy generated by the building will provide enough carbon credits over 25 years to offset the carbon used in its construction.

The newly completed GSK Carbon Neutral Laboratory for Sustainable Chemistry at the University of Nottingham is a completely carbon-neutral structure, the first of its kind in the UK. Part funded by GlaxoSmithKline, the building serves as a hub to catalyse new collaborations with industry. The centre is unique in the UK, not only in its design, but also in its focus on world-leading research activity in sustainable chemistry that aims for the highest ‘clean and green’ standards to minimise environmental impact and ensure that the new chemistry developed is energy and resource efficient, and sustainable. The building is constructed from natural materials to reduce and offset embodied energy. Meanwhile, the energy required to run the laboratory is met by renewable sources with a combination of photovoltaic panels on the roof and heat and power generated from a sustainable biofuel. The building services throughout have been designed to minimise energy use wherever possible, including an exemplar naturally ventilated laboratory. Excess energy generated by the building will provide enough carbon credits over 25 years to offset the carbon used in its construction.

Case study : A glimpse of the future from a world first

The Energy Technologies Building at the University of Nottingham is a research hub like no other. The world’s first in-use, zero carbon, BREEAM Outstanding research centre, it shows the future for green lab design and alternative energy. A unique combination of low-carbon design and energy-generating technology produces surplus heat and electricity which is redirected to a nearby campus building. This not only helps to reduce energy demands in a highly intensive environment, but also serves to keep operating costs down. The complex also features designs to minimise demand for heating, cooling, lighting and ventilation including a biofuel district CHP. The site also features a green roof for rainwater attenuation and to absorb heat gain. The centre’s hydrogen filling station is powered by renewable energy generated by the rooftop PV panels.

The Energy Technologies Building at the University of Nottingham is a research hub like no other. The world’s first in-use, zero carbon, BREEAM Outstanding research centre, it shows the future for green lab design and alternative energy. A unique combination of low-carbon design and energy-generating technology produces surplus heat and electricity which is redirected to a nearby campus building. This not only helps to reduce energy demands in a highly intensive environment, but also serves to keep operating costs down. The complex also features designs to minimise demand for heating, cooling, lighting and ventilation including a biofuel district CHP. The site also features a green roof for rainwater attenuation and to absorb heat gain. The centre’s hydrogen filling station is powered by renewable energy generated by the rooftop PV panels.