Demystifying 4.0

With increased connectivity and boundless data catapulting manufacturing into a new digital age, process and automation specialists Eugene Smethurst and Stephen Mounsey explain what Industry 4.0 is all about and how businesses can plan to stay smart.

Intelligent robots that talk to one another, self-monitoring production lines, customer orders that manage themselves and infinite data stored in invisible clouds; far from a scene in a futuristic film, Industry 4.0 has the potential to dramatically change the way things are made, how people buy and use services and completely transform how factories work.

Not everyone is clear or convinced on what Industry 4.0 is about, so let’s start with the basics. The term Industry 4.0, also known as the Fourth Industrial Revolution, was coined in Germany in 2011 and is used to describe the increasing digital connectivity of customer, product, process and factory through the use of emerging and disruptive technologies, the Internet of Things (IoT), cloud storage and automation. At the heart of this new revolution is data — and lots of it.

The idea being that by harnessing data with emerging, intelligent technologies and machines, manufacturers can collect, store, analyse and share information about their products and the equipment that produce them, making manufacturing more flexible, smarter, quicker and efficient. All of this is expected to become a reality over the coming five to 10 years.

Levelling things out

The German government will be investing €40 billion (£31.6 billion) in Industry 4.0 each year until 2020 to drive innovation and productivity across its manufacturing sectors, according to PricewaterhouseCoopers figures. If other countries invest in and adopt greater automation, developed economies outside of Japan, Korea and Germany could start to compete with low-cost labour economies, helping to level out the production playing field between countries.

The UK government is also allocating significant funding to help businesses digitise manufacturing and embrace the new Industrial Revolution, ultimately helping to enrich the UK and other high value GDP economies. IT services company Accenture estimates the Fourth Industrial Revolution could add up to £359 billion to the UK economy by 2030.

Connect to conquer

So what’s the incentive for businesses to capture more data and connect everything together, and what plans should they put in place to ensure they keep pace? The IoT, which enables the collection and exchange of data between a network of computers, personal devices, sensors and other technologies, with minimal input from humans, is front and centre in the digitisation of manufacturing, and will act as a conduit for data storage and sharing between customer, product and manufacturer.

Using the IoT, businesses can track what and how their customers are buying, leading to faster new product development. They can also gather data from self-monitoring equipment on when parts and machines will need repairing or replacing. Self-learning and autonomous robots will make production lines smart enough to learn how to build things more quickly, massively reducing time to market. Ultimately, manufacturers will be able to enhance their business operations by producing more from less, improving their bottom line.

Siemens, the global technology company, is a good business to learn from. Seen as the Industry 4.0 trailblazer, production at its electronics factory in Amberg, Bavaria, is already largely automated. Machines and computers are responsible for 75 per cent of the value chain. Products made in the factory control their own assembly by using a digital product code to directly communicate to the machines how they need to be built.

Securing the future

With even more data to play with, it’s inevitable that businesses will need to up their cybersecurity to prevent information about their products and processes being stolen, lost or changed. The UK government’s 2014 Information Security Breaches Survey found that 81 per cent of large companies have reported some form of security breach, costing each organisation on average between £600,000 and £1.5 million.

Businesses will need to rely more on real-time encryption, where data is translated into confidential code and password-locked, to ensure their most valuable information is safe.

Early Industry 4.0 adopters will be the first to reap the rewards of a more digital, connected future.

Cloud control

To cope with the increasing flow of information, some companies have started building onsite data centres complete with inbuilt software that joins the dots between information, also known as data discovery platforms. These can also detect and help guard against cyberattacks through site-specific firewalls and encryption.

However, the use of wireless communication to transfer information continues to rise and is leapfrogging the use of hardwired computer systems. It won’t be too long before we see the widespread use of 5th generation (5G) wireless technologies and beyond.

Cloud storage is also gaining popularity. By keeping data in remote servers accessible via the internet, businesses can store vast amounts of information, and instantly add more processing power without the need to constantly invest in more expensive software and computers. Cloud platforms could also open up a whole new world of global collaboration between manufacturers, suppliers and customers, leading to better product development, and efficiencies that link business systems to production and ultimately the end user.

Business as usual

Early Industry 4.0 adopters will be the first to reap the rewards of a more digital, connected future but there’s currently little tangible evidence or models to learn from. Planning ahead is the best place to start; from examining what infrastructure a business needs to support Industry 4.0 technologies and empower data management, to developing a long-term recruitment strategy.

For Industry 4.0 to become business as usual, manufacturers will need to roadmap their own way forward while learning from those who take risks before them, develop strategies to cope with boundless data, figure out how best to use it and know where and how much to invest.

One of the biggest challenges of Industry 4.0 will be to get people to change from the way they’ve always done things. All of these will affect future success and how well manufacturers can compete in our increasingly global production market.

Planning for change

Industry 4.0 brings lots of opportunities for manufacturers to make processes more efficient, products more personalised and drive down costs. So where’s the best place to start?

Invest in people and skills

People will remain the most important part of any manufacturing business. Do employees have the enthusiasm to embrace the future and foster change? Do they have the ability to analyse data to bring real business value and manage those changes? Businesses should also ask themselves how they can help their employees adapt and grow. Training and recruitment will be key to success.

Roadmap your data and technology requirements

This involves conducting a detailed audit to understand the data and technology that you use now, and mapping out a strategy around which systems you’ll need in the future to drive return on investment (RoI) and meet customer, product, manufacturing, data capture and employee training needs. This should be done across manufacturing systems and business operations.

Develop a 4.0 concept

Businesses should devise a detailed ‘what if’ scenario around their data and technology roadmap to consider and decide on the best Industry 4.0 options for them, including the costs involved, expected RoI and inputs and outputs. Ask yourself what’s going to add the most value, drive the greatest efficiencies and help you remain competitive in the long term.

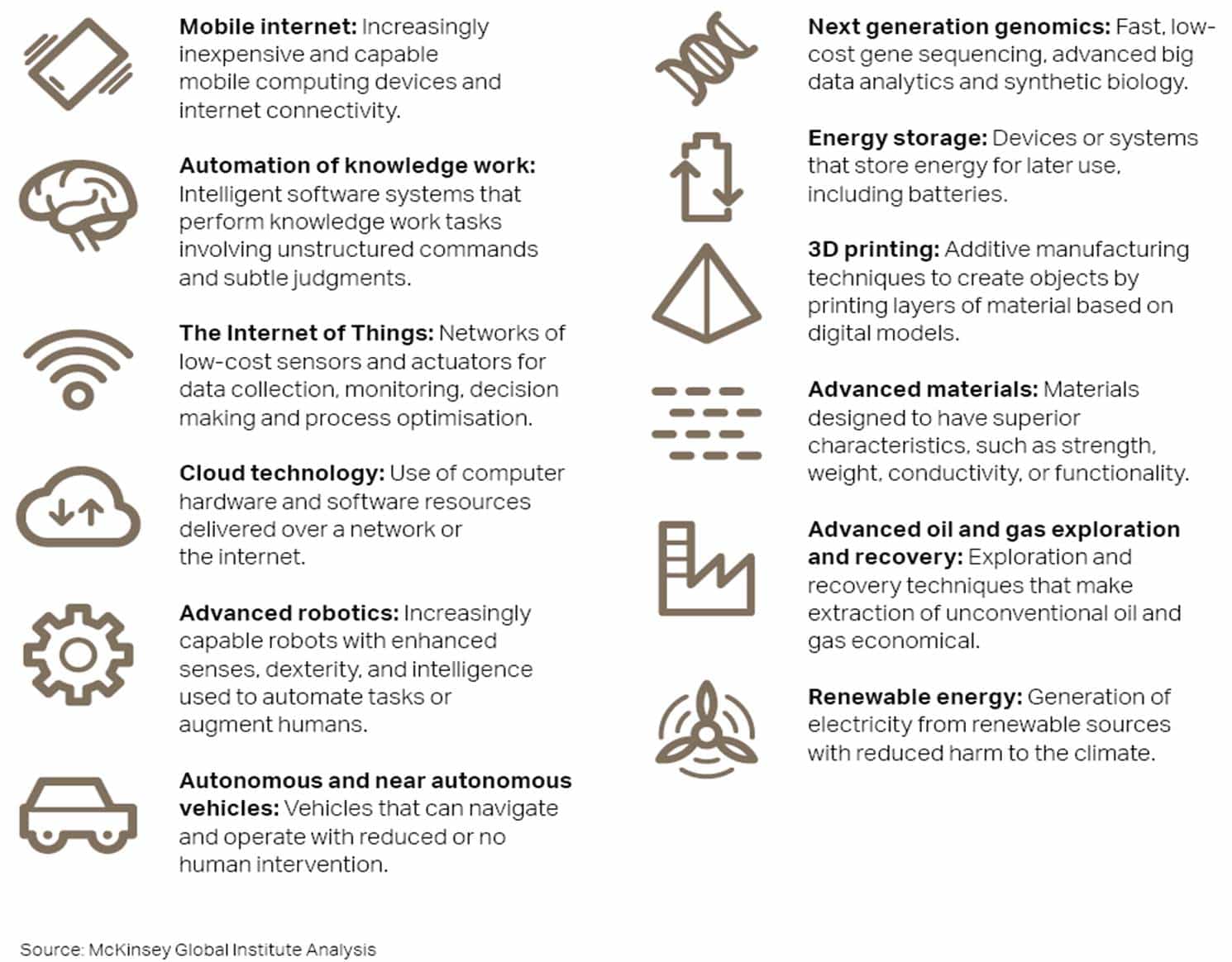

Disrupting the status quo – The 12 disruptive technologies expected to shape Industry 4.0: