LA: Denim City

Indigo Dye Lump. Photo by Evan Izer (Palladian).

In the United States and beyond, denim is an international wardrobe staple. Nowadays it’s nearly impossible to identify an article of clothing embraced more fully than jeans. In the 19th century, jeans began as work-wear for hard labor in mines, factories and fields. Since then, the denim industry has matured into a huge business, bringing in around $14.3 billion in sales in 2012, according to The NPD Group. A study conducted by Cotton Incorporated revealed that the average American owns seven pairs of jeans and nine other denim items. Worn by cowgirls and supermodels alike, jeans have become a tactile, wearable symbol of the American west and the American dream.

#5 from Soft Feel. Photo by Aidan Flaherty.

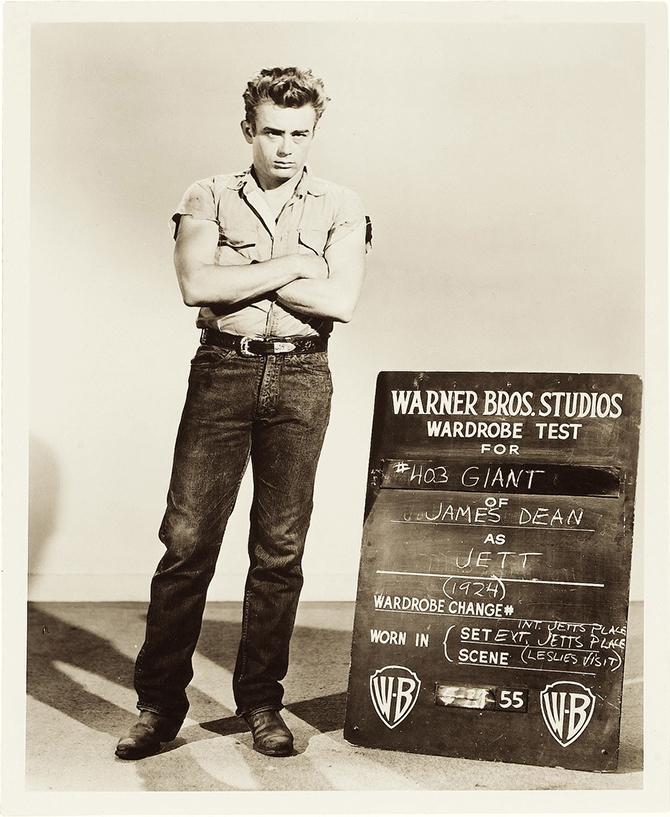

At the center of the denim market lies Los Angeles—the Denim Capital of the world. Hollywood films such as Rebel Without A Cause and The Wild One established James Dean and Marlon Brando as raw denim poster boys and transformed the worker’s trouser into a trademark of the rebel and a growing youth subculture. Today Los Angeles produces 75 percent of the world’s premium denim jeans and is home to numerous premium denim lines including AG, Citizens of Humanity, Paige Denim, and 7 For All Mankind.

James Dean. Photo from the set of “Giant.”

The environmental repercussions of the denim business are significant as well. Conventional denim production employs low-efficiency, energy consumptive processes. A pair of jeans’ life cycle includes: cotton production, fabric production, garment manufacturing, transportation and distribution, consumer use, and waste. On average, fabricating a single pair of jeans requires 2,500 gallons of water, harmful chemicals and vast amounts of energy. A study conducted by Levi Strauss & Co. found that a single pair of jeans emits 32.3 kilograms of CO2; equating to around 71 pounds of CO2 emissions. To illustrate further, this is roughly the same as driving an average vehicle around the United States for 78 miles. Figures associated with the environmental impact of jean production are staggering and have inspired a movement to pursue cleaner, greener denim production.

Aerial shot of denim and dyeing facilities polluting China’s Pearl River.

Levi Strauss & Co. places a great emphasis on embracing “A Product Life Cycle Approach to Denim” while individuals such as Brad Allen Mowry, with companies and organizations such as Olah and theJeansProject, are educating the public on the world of denim production. Cathy Pack, an architect based in AECOM’s Los Angeles office, believes architecture can develop these efforts even further.

Inside a denim laundry – finishing process.

Cathy’s work explores the symbolic and technical connections between architecture and clothing and seeks to identify strategies that apply sustainable design to the world of fashion and clothing production. She believes that sustainable architecture can help elevate and expose one of Los Angeles’ least understood and least-valued industries—fashion. To gain a clearer understanding of how denim is produced here in Los Angeles, Cathy met and interviewed industry professionals including Sheila Foreman, owner of the commercial denim processing facility Garment Industrial Laundry. Cathy’s research stems from a desire to develop eco-efficient denim processing practices and facilities that reduce water consumption, energy consumption, cotton waste and wastewater.

Jeans are slipped onto inflatable rubber legs and sprayed with potassium permanganate to produce a fading effect.

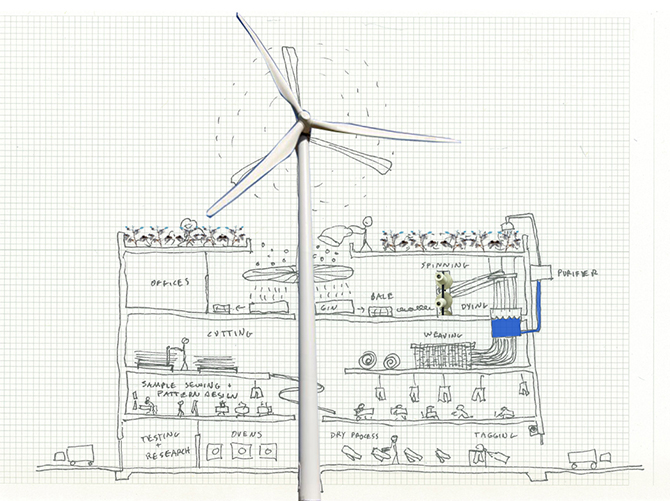

Architecture has the potential to increase the transparency of established consumer systems and reveal the weaknesses of current practices. Cathy sees an excellent opportunity to use public space and spaces of commerce as staging sites for consumer education. She’s proposing the design of a new factory that employs sustainable denim manufacturing practices and provides public display and educational facilities. Ultimately such a scheme offers consumers a unique vantage point onto the denim industry and brings them closer to the products they’re consuming. Aside from consumer education, the introduction of such an architectural response has significant economic implications. Showcasing a city’s speciality, in this case Los Angeles’ denim expertise, through architecture initiates a dialogue that strengthens a city’s economy, helping it evolve into a global metropolis. These types of spatial relationships establish new and exciting opportunities that spark innovation, draw intellectual and economic investment and help solidify a city’s identity.

Whiskers template – whiskers are wrinkled lines added at the groin make the hips appear narrower.

Cathy first presented her research at the “Learning from Los Angeles PechaKucha Night” at the HubLA. Co-hosted by AECOM and the LAForum, the event gave designers, planners and urbanists the opportunity to share their impressions of Los Angeles. Topics included the city’s culinary scene, residential architecture, public space, urban history and design collaboration.

Diagram of Denim Factory by Cathy Pack. Cotton is grown on the roof and thrown down a chute where a wind-turbine-powered cotton gin separates the fibers from the seed. It is spun and dyed, the wastewater treated and used to water the cotton. After being woven and cut, it gets sent to the sewing floor, and from there, processed and shipped out.

Cathy will present her research on Green Fashion at the U.S. Green Building Council Los Angeles’ (USGBC-LA) Green Gala on December 12, 2013.

Aidan Flaherty (aidan.flaherty@aecom.com) is a marketing specialist for AECOM’s Buildings + Places business in the Americas.

Aidan Flaherty (aidan.flaherty@aecom.com) is a marketing specialist for AECOM’s Buildings + Places business in the Americas.

Cathy Pack, AIA, LEED AP BD+C (cathy.pack@aecom.com) is a senior associate with AECOM’s Architecture + Interiors practice.

Cathy Pack, AIA, LEED AP BD+C (cathy.pack@aecom.com) is a senior associate with AECOM’s Architecture + Interiors practice.